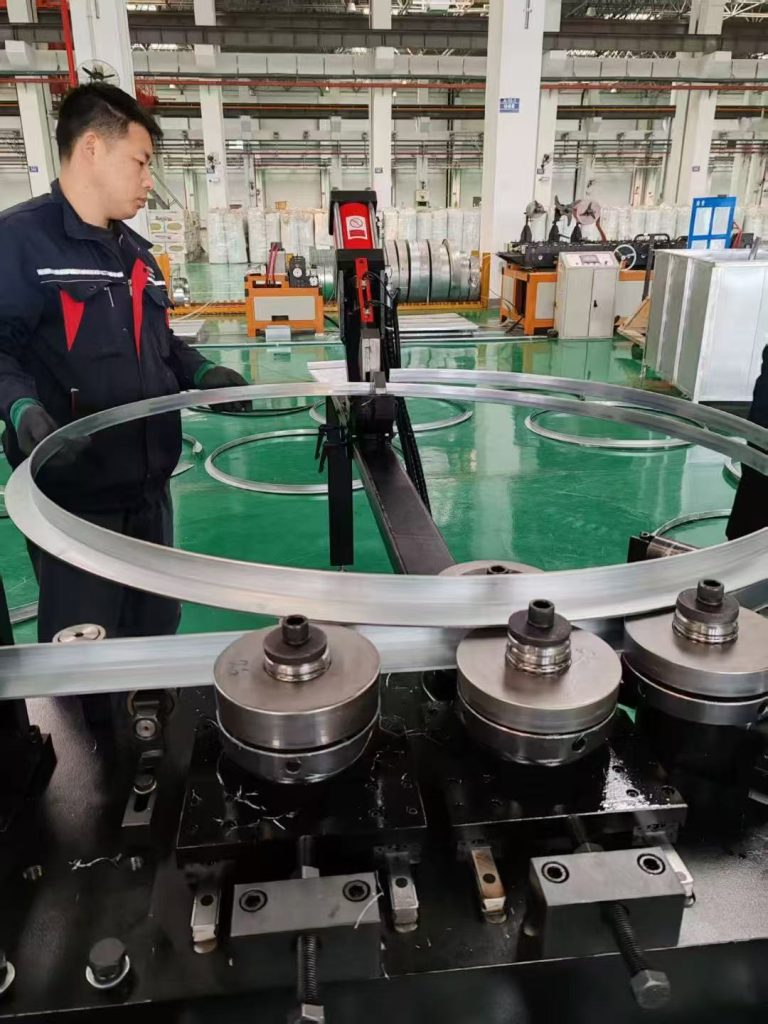

Flange forming machine is widely used in fans, bridge templates, chemical equipment, cable wire racks, mining explosion-proof switches, centrifugal fans and other machinery and equipment industry applications.Flange forming machine uses the moulds on the three rollers to roll all kinds of profiles (e.g., flat steel, channel steel, round pipe or other shaped cross-section profiles.

Flange forming machine is a high-quality and high-efficiency roll-round device to roll carbon steel, stainless steel, non-ferrous metal profiles (angle steel, strip steel, channel steel, pipe, etc.) into rings and flanges with diameters from Φ200 to Φ6000, with a unique structure, a small volume, low energy consumption, high efficiency, noiseless easy to install and use, easy to operate, strong load-bearing capacity, long service life, high speed of roll-rounding, and reliable product quality. Advantages. Instead of the original steel plate discharging, docking, calibration, lathe processing and other complex processes, and saves oxygen, acetylene, labour, raw materials, etc., is the manufacture of flanges of the advanced machine!

Introduction of round flange forming machine:

I. According to the function classification can be divided into: production line and conveying line

II. According to the conveyor form classification can be divided into plane straight line transmission line, plane turn transmission line, inclined upload line and inclined downstream transmission line.

Secondly, the round flange forming machine which to choose, the purchase of assembly line should understand the composition and function of each part of the assembly line

1. Power: the main components of the power part of the assembly line are: gear box, motor, frequency converter, frame and electrical components.

Motor part is mainly the size of the power, manufacturers should buy assembly line according to the width of the conveyor belt, the length of the line, the distribution density of workpiece weight and other circumstances to configure.

2. Body: the main components of the assembly line body part: bracket, guide, conveyor belt, roller, pallet, adjustable feet and other components.

The choice of materials, specifications, quantity of these accessories are determined by the length and use of the line body.

CNC Duct Metal Flange Rolling Machine

The application of angle iron flange production line is very popular in the market, usually the angle iron flange production line adopts a number of measures to solve the feeding difficulty and collimation error caused by the bending of angle steel. In addition it adopts PLC, industrial control machine control, servo motor feeding, high efficiency, stable working precision, the key liquid, gas, electric components all adopt imported products.

Flange type:

1. Pressure vessel flanges are divided into general flanges and reverse flanges according to the overall structure.

2. According to the gasket arrangement, it is divided into two categories: narrow face flange and wide face flange.

(1) Narrow face flanges are flanges in which the gasket contact surface is located within the circumference surrounded by the bolt holes of the flanges, and they are the more widely used flanges.

(2) Wide flange refers to the flange with gasket contact surfaces distributed inside and outside the centre circle of the flange bolts. Generally, it is only used for occasions with very low pressure.

(3) According to the integrality of each part of the flange, it is divided into three forms: loose flange, integral flange and arbitrary flange.

Its characteristics are: loose flange: refers to the flange failed to effectively connect with the container or receiver into a whole flange. Calculation that the cylinder is not with the flange ring to bear the role of the flange torque, flange torque completely by the flange ring itself.

Features of the equipment:

Power system: adopts the front drive mode, which not only improves the stability of the product, but also reduces the waste of materials, and at the same time reduces the failure rate of the equipment.

Circumference meter wheel positioning: on the basis of the original PLC calculation and control of circumference, double bumpers are added to ensure the precision of diameter circumference after flange forming.

Double out shaft cylinder jacking device: In the process of material forming, due to the change of rebound pressure coefficient, this device can keep the normal supply of pressure at any time to ensure the smooth stability of the flange roll rounding process.

Key components: Reducer, electric control, transmission bearings, etc. are all of well-known brands to ensure the reliability and durability of the equipment.

Mould material: Japan Cosmos SKD11 or DC53 material is used, which not only increases the service life of the mould, but also reduces the risk of deformation and breakage.

There is no front and rear end straight loss material, which saves raw material.

Fast rounding speed, reliable precision of finished products, no burr, meet the demand of high precision processing.

HOGI Flange Punching Forming Machine Flange Punching Forming Rolling Machine Manufacturer Rolling Round Punching Automatic Flange Machine Manufacturer Actual Flange Rolling Machine Flat Iron Punching Rolling Round Flange Machine Flange Forming Punching One Machine Servo Ringing Machine

TFT human-machine interface display, touch screen setting, numerical control control system, with module storage and memory function.

Structure: The frame adopts a strong composite combination, and the components are thick, solid and durable. Operation function: with inching/automatic function.

Applicable scope: 30×20mm, 40×20mm, 50×30mm, thickness 3-4mm iron, stainless steel, equal or unequal angle iron and flange diameter Φ160mm-Φ2000mm forming.

Engineering action category: 1. Forming and cutting of each straight angle iron. 2. Forming and cutting of each flange.

Hydraulic system: The working pressure is adjusted steplessly, and the hydraulic circuit adopts a zero-load design, with a low-pole frequency design of the oil pump motor, which effectively reduces the noise and increases the motor efficiency and life.

Electronic control system: equipped with human-machine interface, diameter forming positioning wheel, distance adjustment position scale design, using German magnetic scale with high precision, making it accurate and simple to operate.

Processing speed: 9150mm/min Body length: 4500mm Width: 2000mm Height: 2000mm Total weight: 4.5T

Processing has no loss of front and rear straight parts, high efficiency and reduced costs.