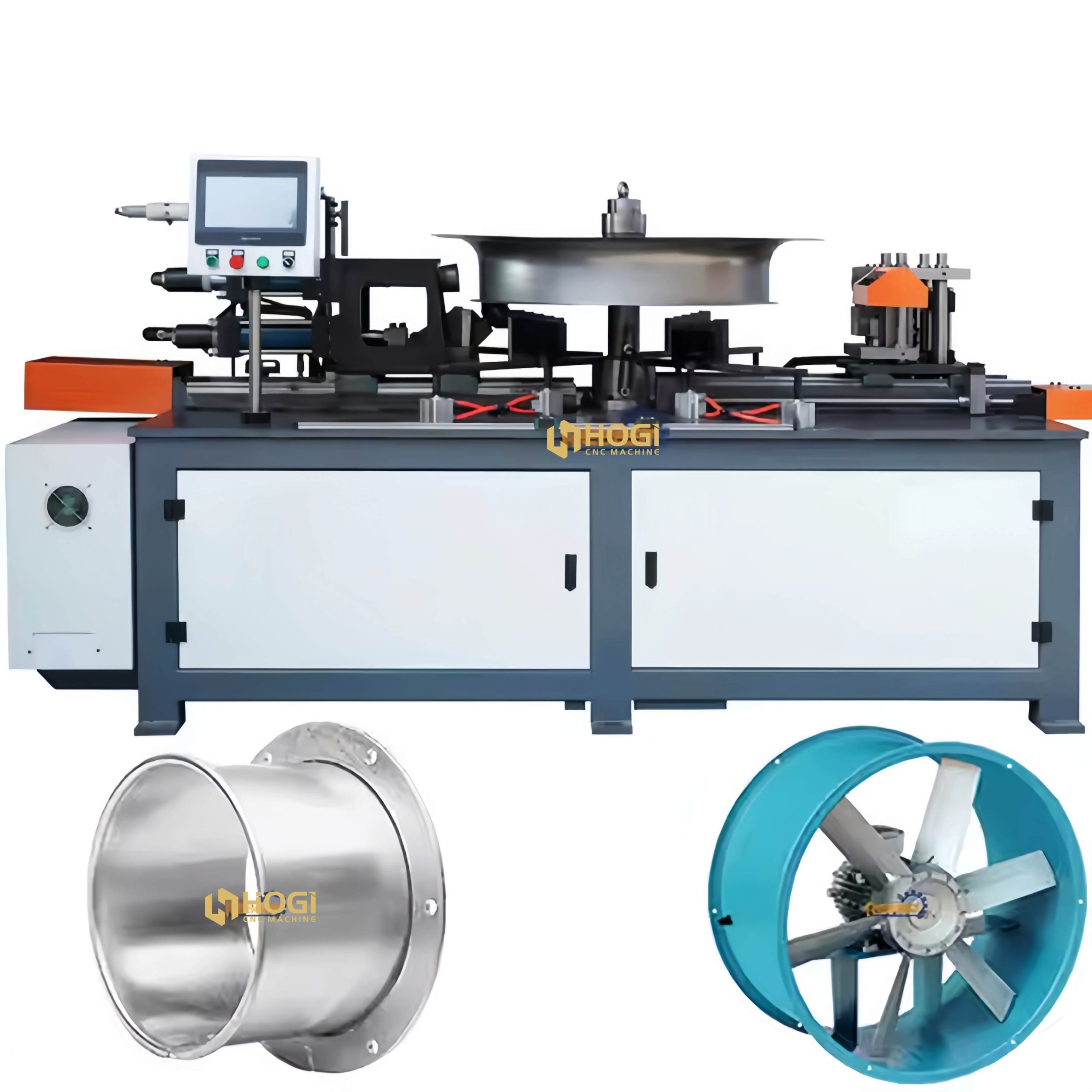

Large industrial fan flange forming

Machine Name: HOGI Large industrial fan flange forming machine

Model:HGFB-2000,HGFB-2500,HGFB-3000,Customizable

Application Industry:This machine is specially designed for flanging both ends of cylinders, and it is suitable for the flanging needs of all kinds of cylinders and fans, whether it is a right angle edge or a curved edge, it can easily cope with it. It is widely used in fan, human defense, ventilation and other machinery industries, contributing to the improvement of production efficiency

Whether it is axial fan casing or centrifugal fan inlet, or the production of round and conical metal cylinder flange edges, this model can cope with it freely.

Technical Service: When ordering our automatic flanging machines, please be sure to provide the following key data:

The range of plate thicknesses planned to be processed;

The range of cylinder diameters to be processed;

The range of lengths of cylinders to be processed;

The width range of the flanging;

The material of the steel plate.

HOGI Automatic hydraulic cylinder flanging punching and trimming machine equipment manufacturer

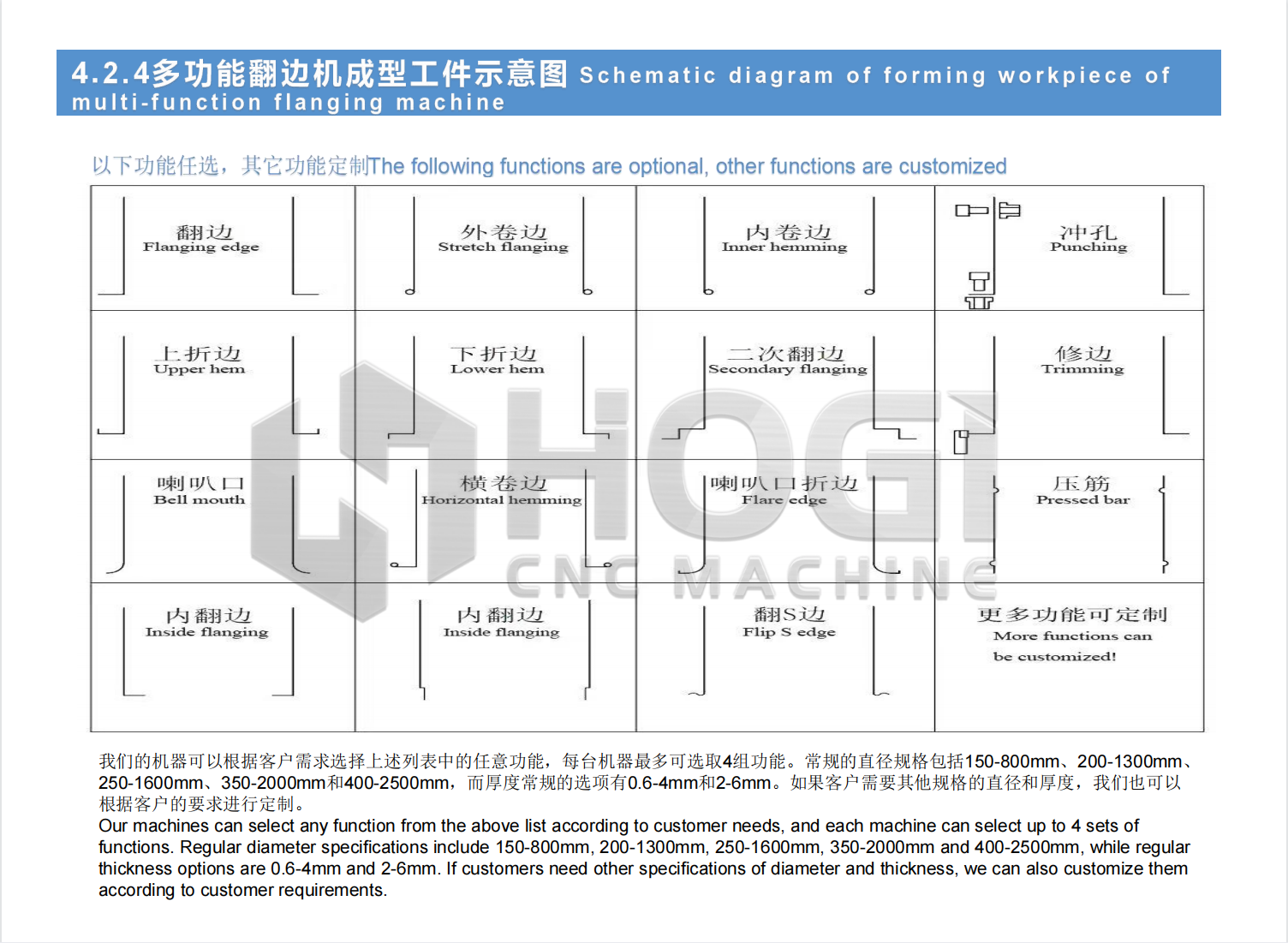

I. Main Functions

1. Flanging function:

– Capable of flanging the edges of cylindrical workpieces to form specific angles and shapes to increase the strength and sealing of the workpieces.

– The height and angle of flanging can be adjusted according to different needs to meet various processing requirements.

2. Punching function:

– Perform punching operation on cylindrical workpieces to make holes of various shapes and sizes to facilitate subsequent assembly and connection.

– Equipped with high-precision punching molds and positioning devices to ensure the precision and positional accuracy of punching.

3. Edge trimming function:

– Trimming the edges of cylindrical workpieces, removing burrs, flying edges and other undesirable phenomena, making the edges of workpieces smoother and neater.

– The use of advanced trimming tools and processes to ensure the quality of trimming.

4. Demanding customization:

-Can be customized according to the customer’s actual demand for the corresponding functions, such as: turning flare, upper folding edge, compression rib, rolled edge and so on.

II. Technical features

1. Hydraulic drive system:

– Provide powerful power output to ensure the stability and reliability of the equipment during processing.

– Precise pressure and speed control can be realized to meet the processing requirements of different workpieces.

2. High degree of automation:

– Adopt PLC control system to realize automatic operation, reduce manual intervention and improve production efficiency.

– With automatic feeding, positioning, processing and unloading functions, easy and fast operation.

3. High precision processing:

– Adopting precise molds and cutting tools, as well as advanced processing technology to ensure processing accuracy and quality.

– It can realize high-precision flanging, punching and trimming of cylindrical workpieces to meet the processing needs of high-end products.

4. Multi-function integration:

– The three functions of flanging, punching and trimming are integrated in one machine, which reduces the equipment footprint and investment cost.

– It can be used in combination according to different processing needs, improving the versatility and flexibility of the equipment.

5. Safe and reliable:

– Equipped with perfect safety protection devices, such as emergency stop button, safety grating, etc., to ensure the safety of operators.

– The equipment runs stably, with low failure rate and easy maintenance.