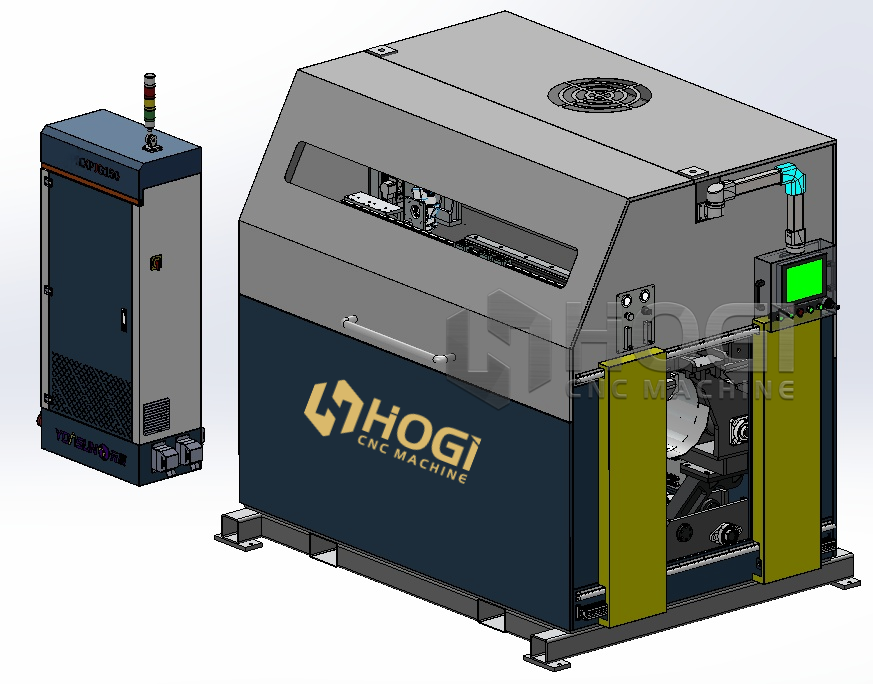

Automatic Seam Welding Machine With Clamping system

Machine Name: Automatic Seam Welding machine

Model: HG-ATZ1540, Customized

Application Industry: Fully Automatic Longitudinal Seam Welding machine for ventilation pipe duct cylinder chimney system With automation clamping system.Laser Welder.

Max Length 1000mm 1500mm

Welding Diameter 80mm-400mm

Welding Thickness 0.5-3mm

Technical Service:

Automatic Clamping straight seam welding machine Laser welder,Widely used in straight seam welding of cylinders.

HOGI Automatic Clamping system Longitudinal Seam welding machine with Laser Welder

The automatic straight seam welding machine is an automated straight seam laser welding equipment developed by HOGI, which is mainly used for straight seam welding of cylindrical, elliptical and square tubes made of stainless steel, carbon steel, galvanized steel, aluminum and other metal materials. The equipment adopts automatic walking mechanism and pneumatic clamping device, equipped with special copper pressure foot to ensure safety, and realizes single-sided welding and double-sided forming.

Product name:Automatic Clamping straight seam welding machine Laser welder

Product Model:HG-ATZ1540

Maximum machining stroke:φ400*L1500mm

Equipment footprint:3800*1900*2200mm(L*W*H)

Equipment site dimensions:4500*3000*2200mm(L*W*H)

Product use: Widely used in straight seam welding of cylinders.

HOGI Fully Automatic Clamping system Longitudinal Seam Laser Welding machine

Hogi’s latest research and development of fully automatic seam welding machine, duct seam welding machine, stainless steel fully automatic straight seam pipe automatic welding machine

The CNC system starts with one button, and no manual intervention is required throughout the process!

A new type of clamping and positioning system structure for straight seam automatic welding machines. This innovative design uses advanced technology and automatic control systems to instantly adjust the clamping centering position and angle, greatly improving the correction speed, which means higher production efficiency and more reliable welding quality. The new structural design is more compact and more adaptable to different working environments, improving the stability of the equipment while reducing maintenance costs. This innovation brings a fast, efficient and reliable beam correction method to the welding industry, which is expected to be widely used in the manufacturing industry to improve production efficiency, reduce costs, and ensure welding quality.

HOGI Automatic Clamping system Straight seam Laser welding machine