An Automatic Welding Machine For Tanks guarantees precise, consistent, and amazing welds for large garage answers. It improves performance, reduces human error, and supplies durable, leak-proof seams important for industries like oil, gasoline, water, and chemical processing. With advanced automation, those machines decorate productivity whilst making sure protection and reliability in modern tank fabrication strategies.

Working Mechanism of Automatic Welding Machines

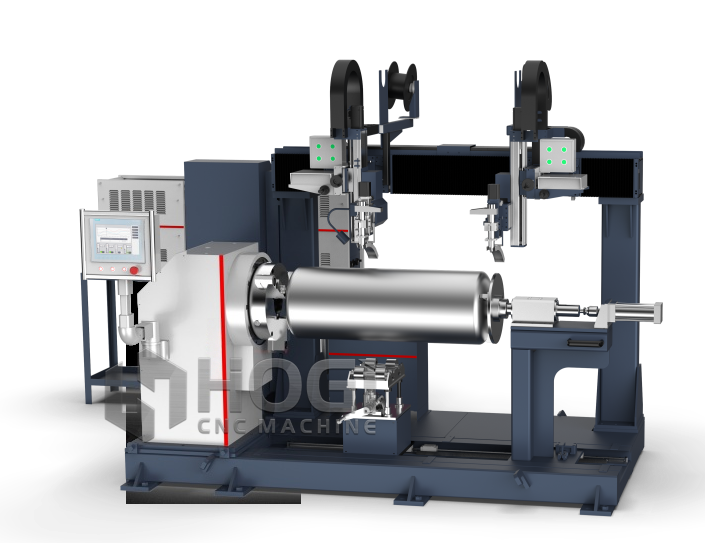

An Automatic Welding Machine For Tanks in China operates via superior control systems that control welding parameters, electrode positioning, and pace. The device acts along the circumference or longitudinal axis of the tank, developing a non-stop and uniform weld. Depending on the design, the system may also encompass submerged arc welding, gas metallic arc welding, or other automatic techniques. Sensors and managed panels make sure accuracy, reduce human errors, and provide consistency even in large-scale production.

Types of Automatic Welding Machines for Tanks

Numerous styles of Automatic Welding Machine are used within the fabrication of tanks. A few are designed for horizontal seam welding, whilst others are specialized for vertical or circumferential welding. Rotational furnishings allow the tank to be located for correct welding, even as robotic hands and mechanized torches take care of the welding technique with precision. Portable computerized welding machines also are to be had, providing flexibility for onsite fabrication and restore paintings. Each kind is selected based totally on the dimensions, thickness, and material of the tank being synthetic.

Applications in Tank Fabrication

Computerized welding machines are extensively used inside the production of tanks throughout numerous industries. In the oil and fuel quarter, they’re vital for constructing storage tanks that may resist extreme stress and environmental conditions. In the water supply enterprise, those machines help in fabricating large water storage tanks with leak-proof seams. The chemical processing zone relies on computerized welding to ensure the integrity of tanks that preserve corrosive substances. Similarly, meals and beverage industries use them to build stainless steel tanks that meet hygiene and protection requirements.

Advantages of Automatic Welding Machines for Tanks

One of the maximum massive blessings of the use of Automatic Welding Machine For Tanks Supplier in China is the ability to obtain uniform weld exceptional throughout massive structures. These machines reduce the dependency on professional guide welders, bearing in mind steady results no matter operator experience. Automated welding enhances productivity by appreciably reducing welding time whilst preserving precision. The decreased errors price also lowers the chances of expensive remodel, enhancing usual efficiency in tank fabrication. Furthermore, using the automatic era minimizes operator fatigue and will increase place of work safety.

Renovation And Operational Considerations

For sustained overall performance, Automatic Welding Machine For Tanks require proper renovation. Normal calibration of the manipulate systems, inspection of welding torches, and tracking of electricity resources are important. Operators have to be taught to address the machines, screen parameters, and ensure safety protocols. Preventive protection reduces downtime and extends the life of the system. Protection is likewise critical, as the welding system includes excessive warmth and electric currents. Right defensive, air flow, and protecting devices are crucial for secure operation.

About Automatic Welding Machine For Tanks

Automatic Welding Machine For Tanks Manufacturer in China has revolutionized the fabrication system, supplying unequalled precision, pace, and sturdiness. Its programs throughout a couple of industries spotlight its importance in creating dependable and long-lasting garage answers. With technological improvements and proper protection, those machines will preserve to play an important position in meeting the developing demands of industrial tank production.