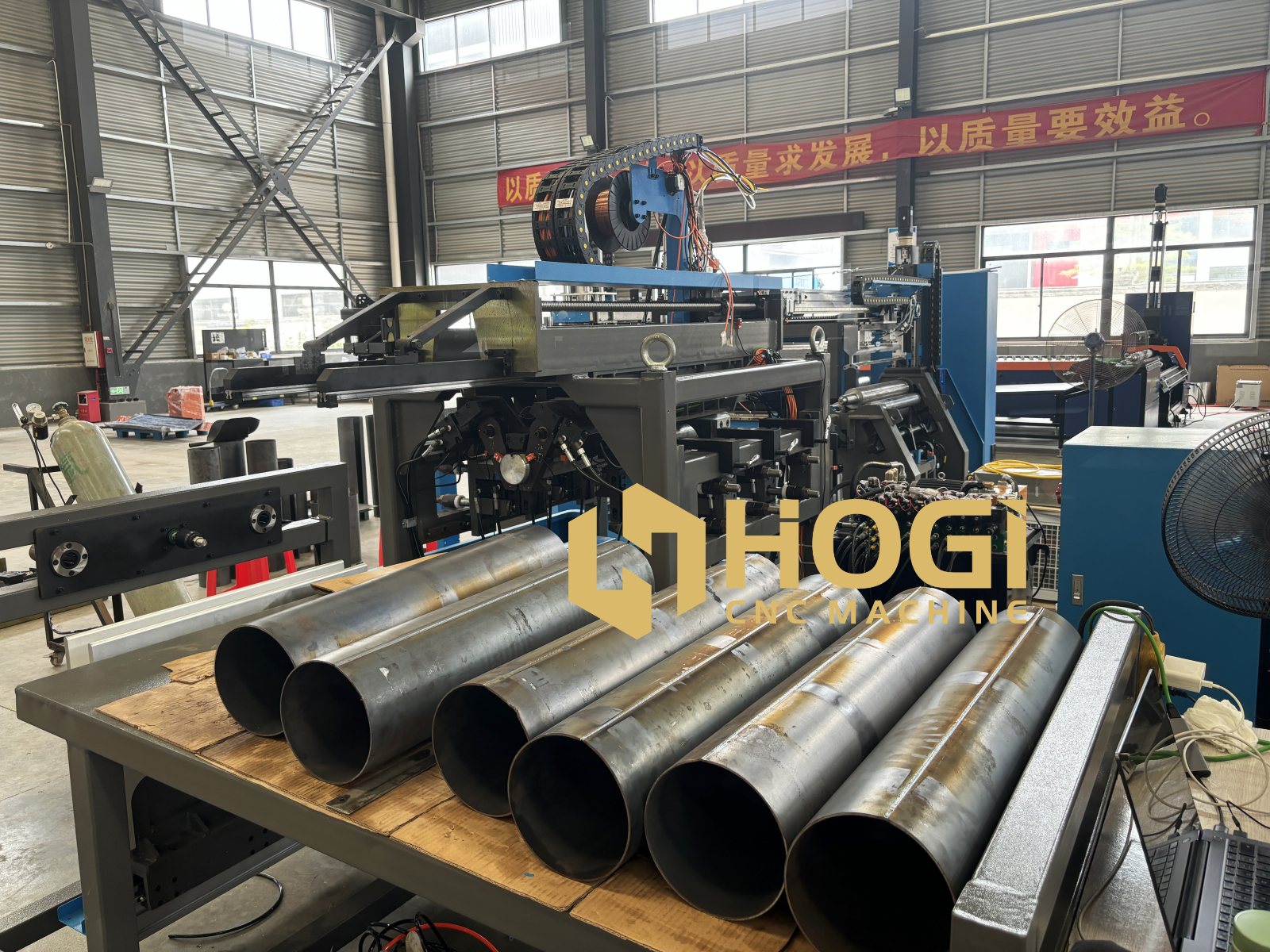

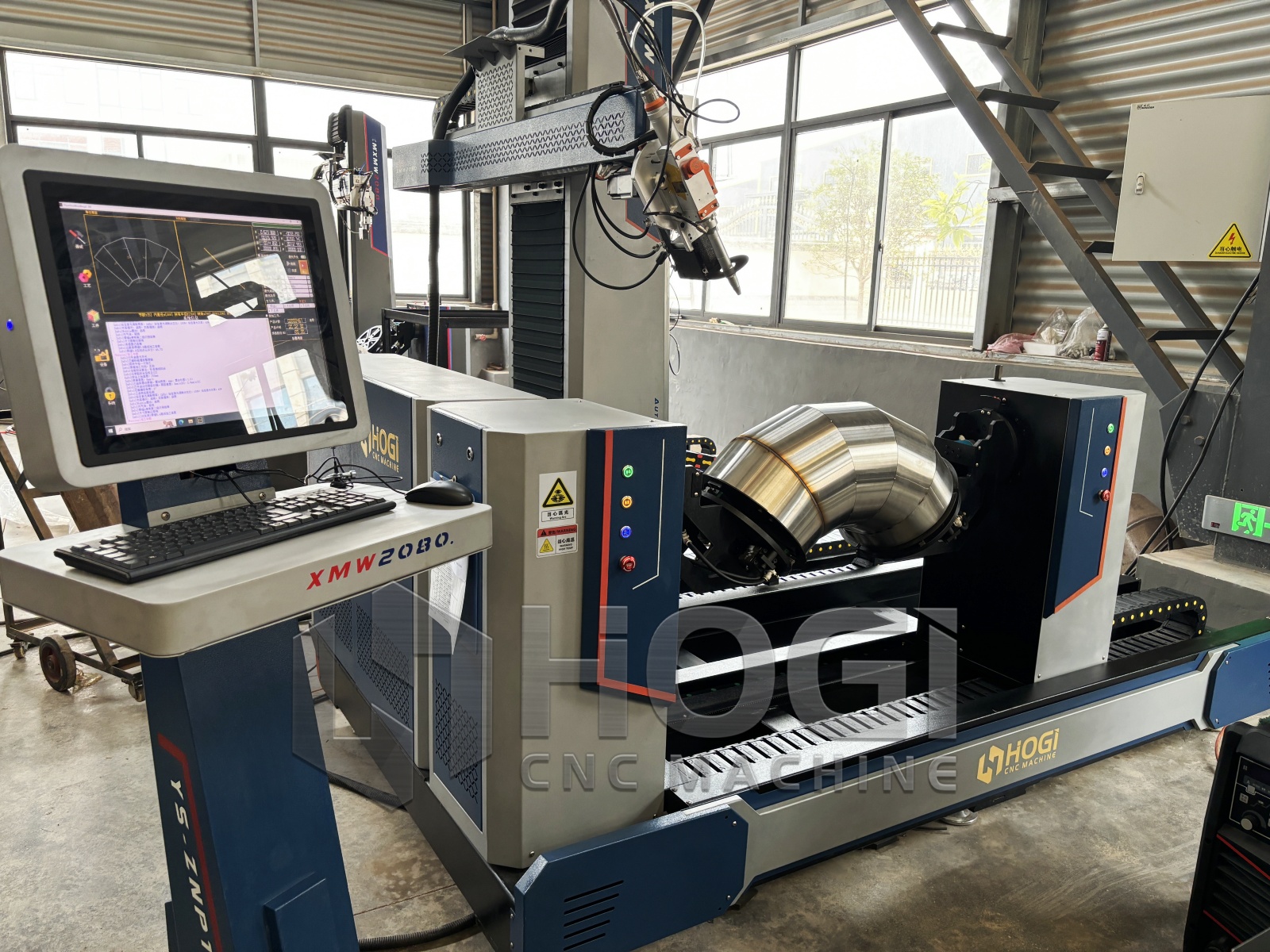

HOGI Industrial fan duct rolling welding automatic production line

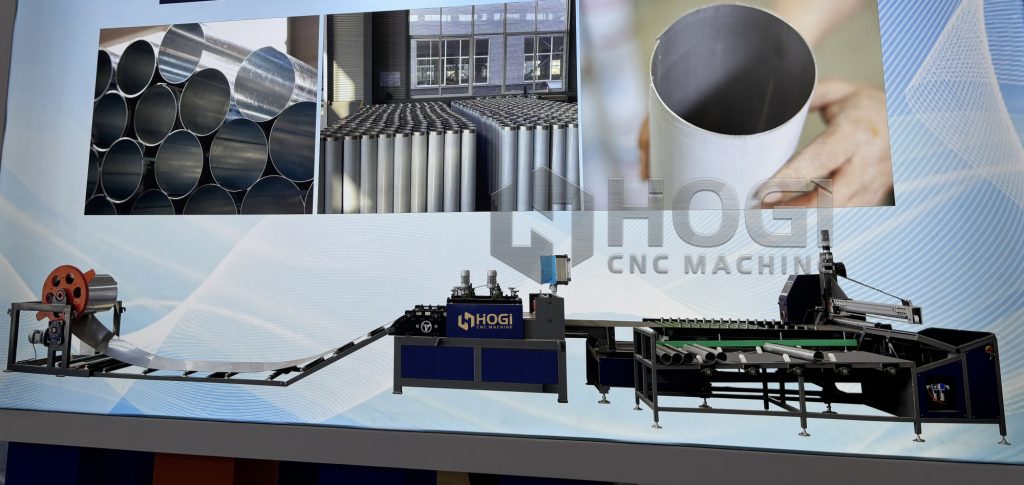

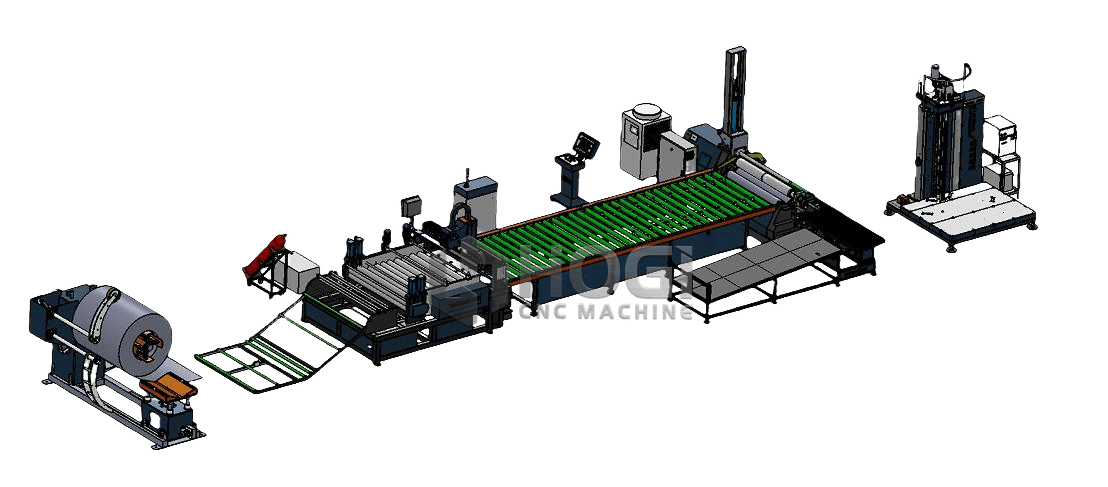

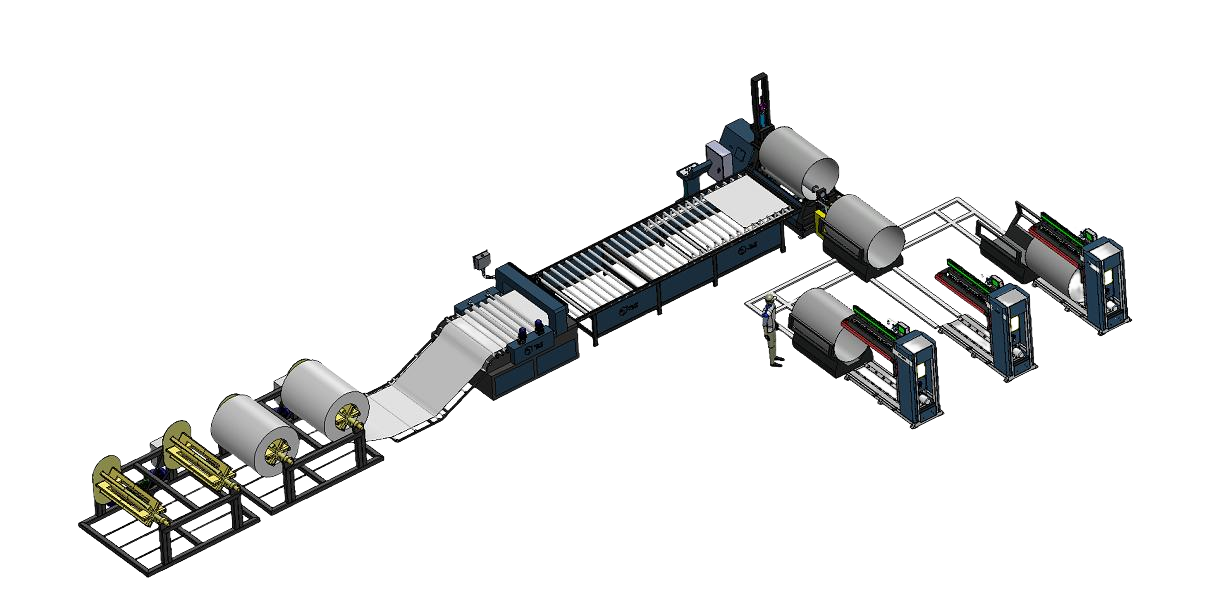

The rolling production line equipment consists of hydraulic material rack, leveling machine, laser cutting, conveying platform, hydraulic four-roller rolling machine, discharging platform, vertical straight seam welding and other structures. It is used to replace manual cutting, rolling, welding, and the equipment is simple to operate and easy to use. High production efficiency.

Automation Solutions

HOGI develops, designs, manufactures and sells intelligent welding, cutting and rolling equipment in the fields of ventilation and environmental protection engineering, fire protection and civil air defense, and heating and cooling ventilation fans, realizing automated, intelligent and parametric production.

Fully automatic four-roller plate rolling machine production line with automatic feeding, rolling and discharging, and automatic welding process.

Manufactures stainless steel ducts, carbon steel air cylinders and ventilation ducts. Various cylindrical bodies in fan fire fighting equipment and automobile industries

Customized Solutions

Industrial fan duct HVAC complete set of automatic rolling welding equipment Electromechanical pipeline rolling welding forming equipment

Customized automatic rolling tunnel welding solution based on customer product requirements, the latest technology solution!

HOGI Fully hydraulic or fully servo driven CNC 4-roller rolling machine, high efficiency and energy saving (drive efficiency is 60% higher than traditional ones), safer and more reliable in rolling than other types of rolling machines

HOGI has advanced technology, the system automatically formulates the rolling program, intelligent control, full hydraulic drive, and realizes the automatic rolling of CNC plate rolling machines. It is a high-efficiency equipment for batch rolling of circular multi-section arc, square, conical, and special-shaped workpieces.

Automated Control

The equipment can monitor the operation process in real time during operation, and many rolling process parameters can be set on the touch screen.

The equipment operation platform has buttons such as start, stop, and emergency stop.-

Automatic Rolling Line

HOGI Small diameter rolling automatic production line

HOGI Ventilation duct automatic rolling production line

HOGI Industrial fan rolling welding production line

HOGI CNC Machines

HOGI continues to invest in industries such as industrial fans, civil air defense pipelines, and environmental ventilation. From angle iron punching machines, angle iron flange automatic welding, CNC automatic rolling machines, straight seam welding (vertical/horizontal), automatic flanging machines, shrimp elbow automatic welding, fan impeller automatic welding, related line automatic welding, round flange automatic welding, pipe-to-pipe automatic welding, to a complete set of laser cutting production lines and round pipe rolling welding production lines, the company can provide a one-stop solution. The professional R&D team escorts the product mechanical structure, software control, and process route; the capable production management team strictly controls the equipment quality; and the efficient after-sales team provides customers with considerate services. Actively innovate and strive for excellence to make welding easier.

Why HOGI CNC

HOGI CNC machine has been continuously investing in industrial fan, human defence pipeline, environmental protection ventilation and other industries, from angle iron punching machine, angle iron flange automatic welding, CNC automatic roll round machine, straight seam welding (vertical/horizontal), automatic flanging machine, shrimp elbow automatic welding, fan impeller automatic welding, automatic welding of the related line, round flange automatic welding, pipe butt automatic welding, CNC spinning machine to the complete set of laser cutting production line, round pipe coiling and welding production line, the company can provide one-stop solutions and global services. The professional R&D team protects the mechanical structure, software control and process route of the products; the competent production management team strictly controls the quality of the equipments; the efficient after-sales team provides customers with attentive service. Positive innovation, keep improving, let welding become more simple.

Direct Manufacturer

Quality Control

Local Support

What They Say

Testimonials

"HOGI Straight seam welding machine Automatic longitudinal seam welding machine Longitudinal seam welding equipment Fully automatic seam welding machine Horizontal straight seam welding machine Argon arc laser straight seam welding machine."

Spain Customer

"Different enterprises may have different processing requirements, multi-function automatic flanging machine can be customized according to the specific needs of customers. Some customers need reinforcement to increase the strength of the workpiece, some customers need to make a flare and so on, hogi's multi-function automatic flanging machine can provide personalized customized service for enterprises to meet their special processing needs."

Colombia customer

"HOGI hydraulic four-roller plate rolling machine rolls carbon steel and stainless steel into round shapes with the latest technology, parameterized digital CNC system, high efficiency and high configuration."

USA Designation

"HOGI customizes oval 4-roller plate rolling machine according to customer product requirements. Small and precise"

France 2024 Dec