In the industrial and civil fields, fans are the key equipment to realize the functions of ventilation, air exchange and dust removal. Centrifugal fans and axial fans, as the two most common types of fans, are both used for gas transportation, but they differ significantly in terms of working principle, structural design, performance performance and application scenarios. This article will help readers quickly understand the core differences between centrifugal fans and axial fans through comparative analysis.

There are many types of fans, among which the most widely used and common, are the two types of centrifugal fans and axial fans. Here we briefly introduce the difference between the two!

1, the exhaust direction is different

axial fan fan inlet and outlet is in a parallel line. Centrifugal fan exhaust direction perpendicular to the air inlet, can be before and after the specified direction of exhaust.

2, the power is different

axial fan is the gas in the rotation of the impeller to complete the axial movement, the movement produced by the wind pressure is very small, but the wind volume is relatively large. Centrifugal fan through the impeller rotation to form centrifugal force for the transmission of gas, generally need to be closed and installed, the wind pressure is relatively large, but the air volume is not large.

3, the shape of the structure is different.

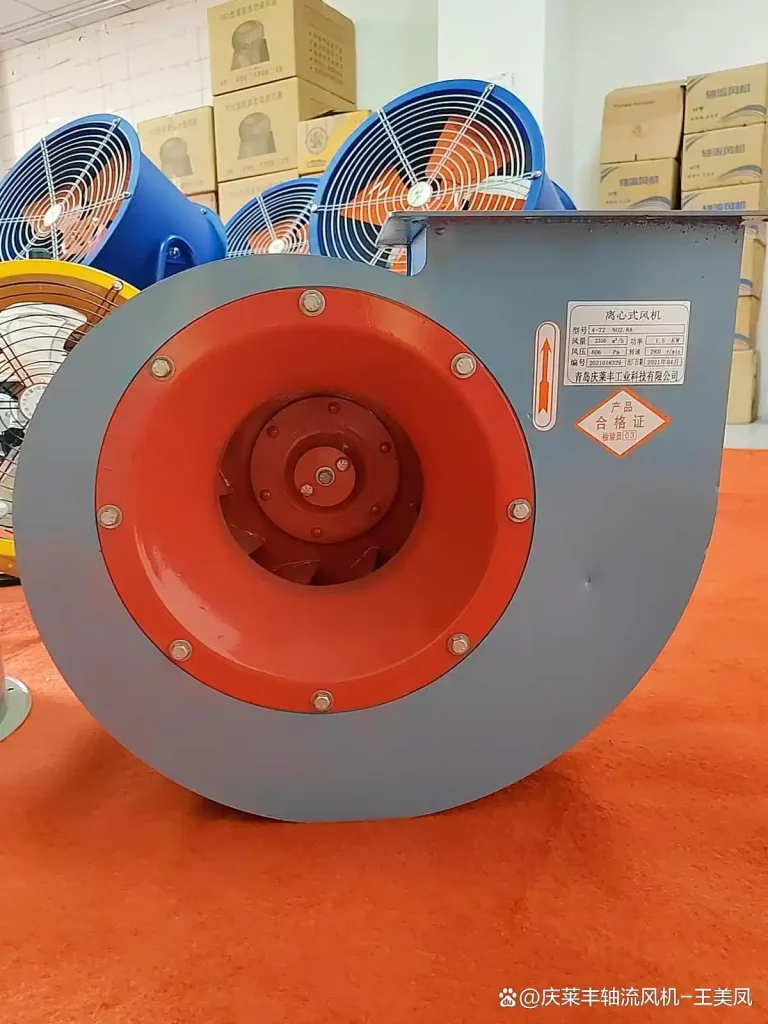

Axial fan motor and impeller are installed in a cylinder, its shape is also a cylinder. Centrifugal fan casing shape is a spiral linear worm shell structure.

4. Different installation methods

Axial fan installation is more convenient, pipeline fan can be installed directly in the pipeline or wall, fixed fan installation through the base for fixing and other ways. Centrifugal fan installation method more steel structure of the bracket, bracket in the installation should be maintained in a straight, reliable state, buried in the wall part of the wall should be deep into the wall at two thirds, in the use of bolts should be increased to prevent the bracket by the vibration of the gasket and the loosening of the situation.

5, maintenance is different

Mainly reflected in the maintenance workload, axial fan basic maintenance-free, but centrifugal fan in continuous operation after the need to add cooling water, check the impeller and replace the lubricating oil.

Characteristics of centrifugal fan:

1, large flow: centrifugal fan can handle a large amount of gas, so that it can reach a high speed in a short time.

2、Low noise: centrifugal fan runs at a lower speed, more stable and less noisy.

3, safe and reliable: centrifugal fan body is made of steel plate, reasonable structure, stable and solid, running with automatic protection devices, will not cause safety problems due to abnormal operation.

4, Easy to maintain: centrifugal fan maintenance is simple, only need to regularly check the oil, belt and other parts of the life, maintenance can be carried out to reduce the use of cost and extend the service life of the machine.

Characteristics of axial fans:

1, high efficiency: able to produce a large air volume under a small power input.

2, low noise: fan in the operation process produces relatively low noise. This is a series of noise reduction measures such as vibration damping devices, sound insulation materials and other noise reduction measures adopted in the design and manufacturing process, which effectively reduces the noise of the fan and makes it quieter in the process of use.

3, small size: relative to other types of fans, has a smaller volume. This makes the axial fan more flexible in installation and arrangement, can be installed in places with limited space, and will not take up too much space.

4、Light weight: easy to carry and install.

5, good adjustment performance: can adjust the wind volume and wind pressure according to the need. So that the fan in different engineering situations can be flexible to meet different needs.

6, high reliability: can run stably and have a long service life. This is in the manufacturing process of the fan using high-quality materials and new advanced technology, so that the structure of the fan is strong and reliable, while reducing the frequency of maintenance and replacement.

In general, axial fans and centrifugal fans have their own advantages and disadvantages, and the choice of which type needs to be based on actual needs. When choosing a fan, you need to consider a number of factors such as air volume, wind pressure, noise, stability, reliability, energy consumption and maintenance costs. It is believed that in the future development, with the continuous progress of technology and application requirements, both axial fans and centrifugal fans will have a lot of space and potential for development.

Axial fan and centrifugal fan are two different products inside the fan category, the main function is also the environment of the air ventilation equipment.

1, axial fan axial fan, the use of a very wide range, is the same direction as the axis of the blade of the air flow, such as electric fans, air conditioning fan is the axial flow way to run the fan. The reason why called “axial”, because the gas flows parallel to the fan axis. Axial fans are usually used in applications where the flow rate is high and the pressure is low. Axial fans are fixed in position and move air. Axial fan is mainly composed of fan impeller and casing, simple structure but very high data requirements.

2, centrifugal fan centrifugal fan is rely on the input of mechanical energy, increase gas pressure and discharge gas machinery, it is a kind of slave fluid machinery. Centrifugal fan is widely used in ventilation, dust removal and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings; ventilation and induced draft of boilers and industrial kilns; cooling and ventilation in air-conditioning equipment and household appliances; drying and selecting of grains; inflating and propelling of wind tunnels and hovercrafts, and so on.

The core difference between centrifugal fans and axial fans

1, the working principle: the difference between centrifugal force and axial thrust

The working principle of centrifugal fan and axial fan is the most fundamental difference between them. Centrifugal fan through the rotating impeller will be thrown out of the gas, the use of centrifugal force so that the gas to obtain kinetic energy, and through the worm shell will be converted into pressure energy. The gas flows in a radial direction inside the fan and eventually exits through the worm housing outlet. This principle allows centrifugal fans to produce high pressures but relatively low flow rates.

In contrast, the axial fan works on a different principle. It rotates the impeller so that the gas flows in the axial direction, and the gas acquires kinetic and pressure energy under the action of the blades. Because the direction of gas flow is parallel to the axis of the impeller, the axial fan is able to realize a large flow rate of gas delivery, but the pressure it generates is relatively low. This principle determines that axial fans have a particular advantage in high flow and low pressure situations.