***Technology empowers the future-HOGI CNC machines

***HOGI CNC MACHINES is a high-tech enterprise engaged in the research and development of automatic welding machines, industrial automation welding and cutting equipment manufacturing and technical services.

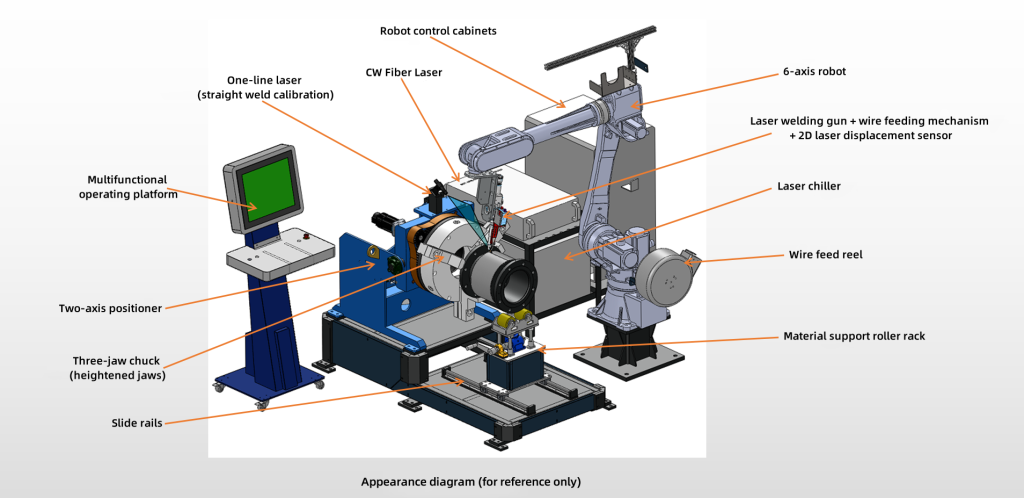

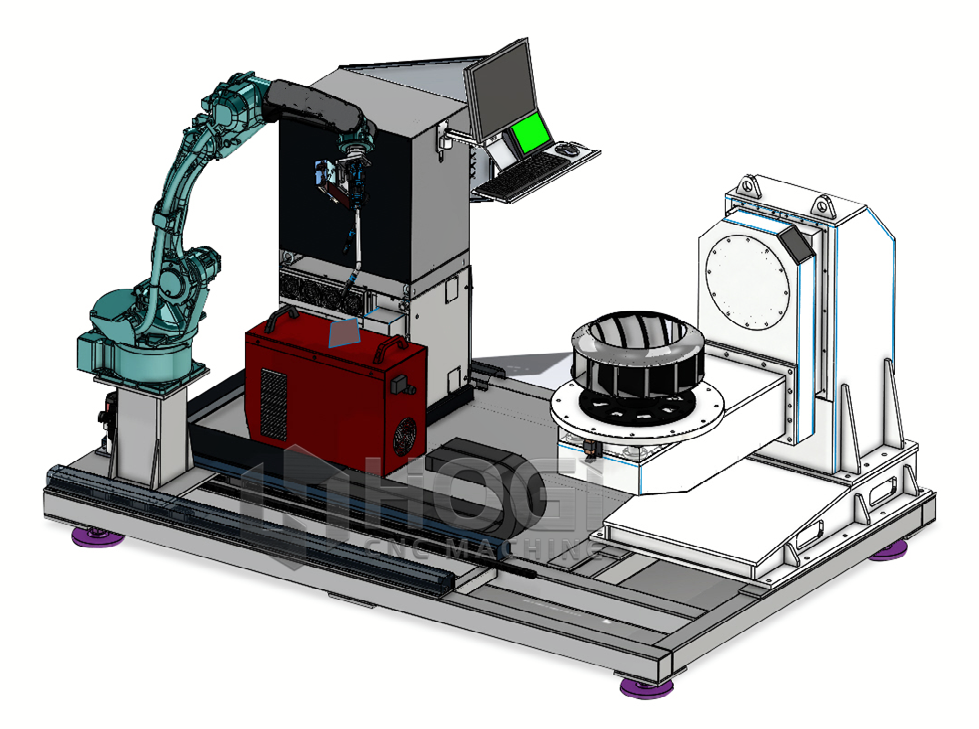

- Robot duct flange laser welding machine

- Robot duct laser automatic welding machine

- Stainless steel duct flange automatic welding machine

- Double-gun automatic girth welding

- Automatic clamping system straight seam welding

- Intersecting line welding robot

- Fan impeller welding system

- Fan impeller robot automatic welding machine

- Centrifugal fan robot welding machine

- Vertical volute double-gun automatic welding

- Vertical girth welding machine

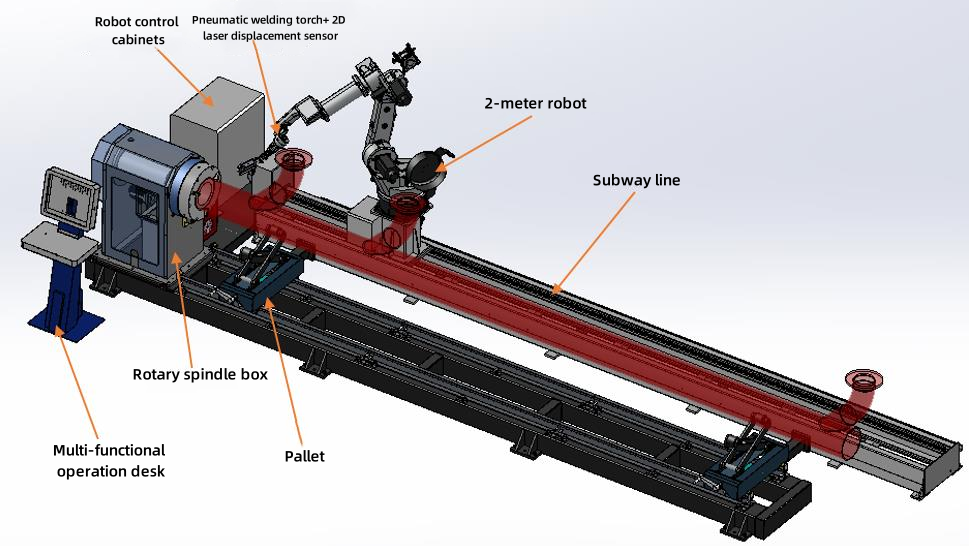

- Single-gun tube butt welding solution

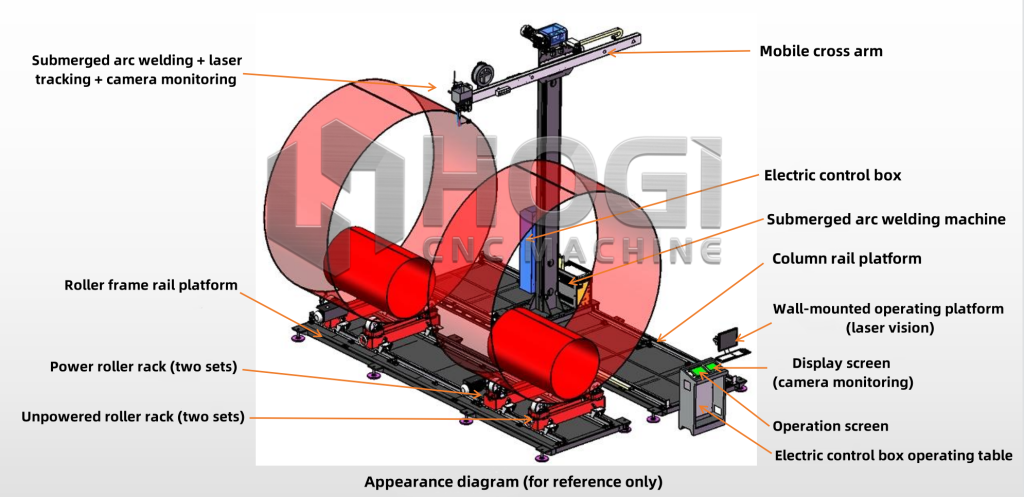

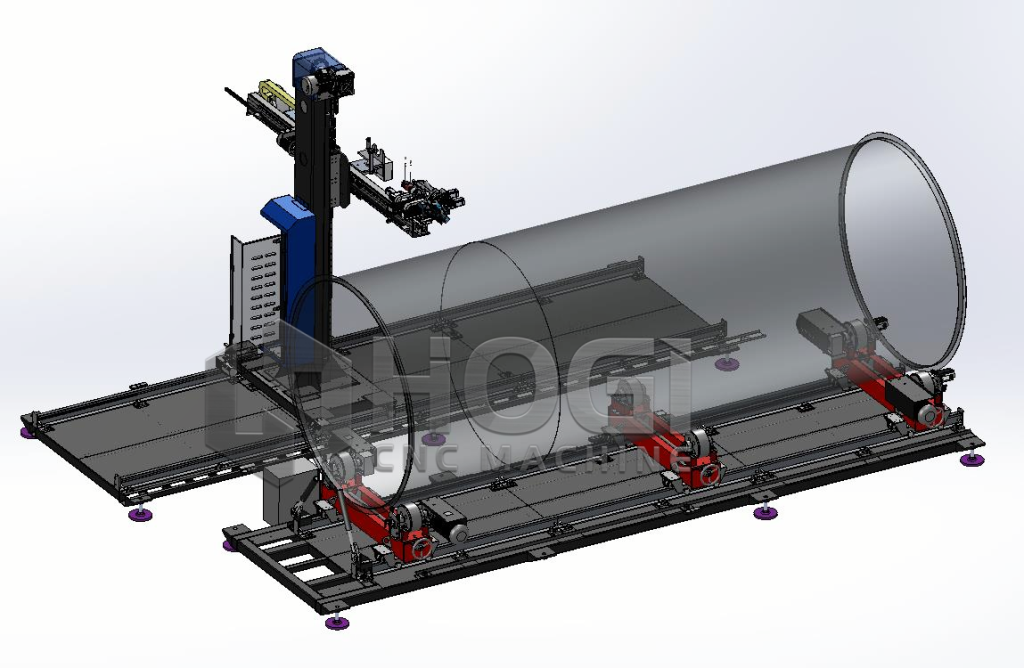

- Round tube straight seam submerged arc welding

- Angle iron flange automatic welding machine

- Heavy-duty pipe flange horizontal girth welding machine

Compared with intelligence, automation is more for enterprises, making the process simpler, more efficient and time-saving. In general, automation is to save time, trouble and labor by manually controlling the machine, so as to ensure quality and efficiency. As a typical example of automation, the automatic welding machine has greatly improved the problems of difficulty in recruiting workers, high risk and slow speed in the welding field.

***Features of automated welding technology:

1. The automatic welding machine is relatively fast, deep, and not prone to deformation during operation.

2. It can perform multi-beam processing and multi-station processing at the same time, making the welded parts more precise.

3. The automatic welding machine can perform micro welding. When the equipment is focused, it can obtain a very small spot, the positioning is very accurate, and a large number of simultaneous production can be performed.

4. The flexibility of the equipment is very strong. If some parts are difficult to access, non-contact welding can be performed, and the effect is also very good.

5. Even in a greenhouse or other special environment, welding can be performed.

axial fan