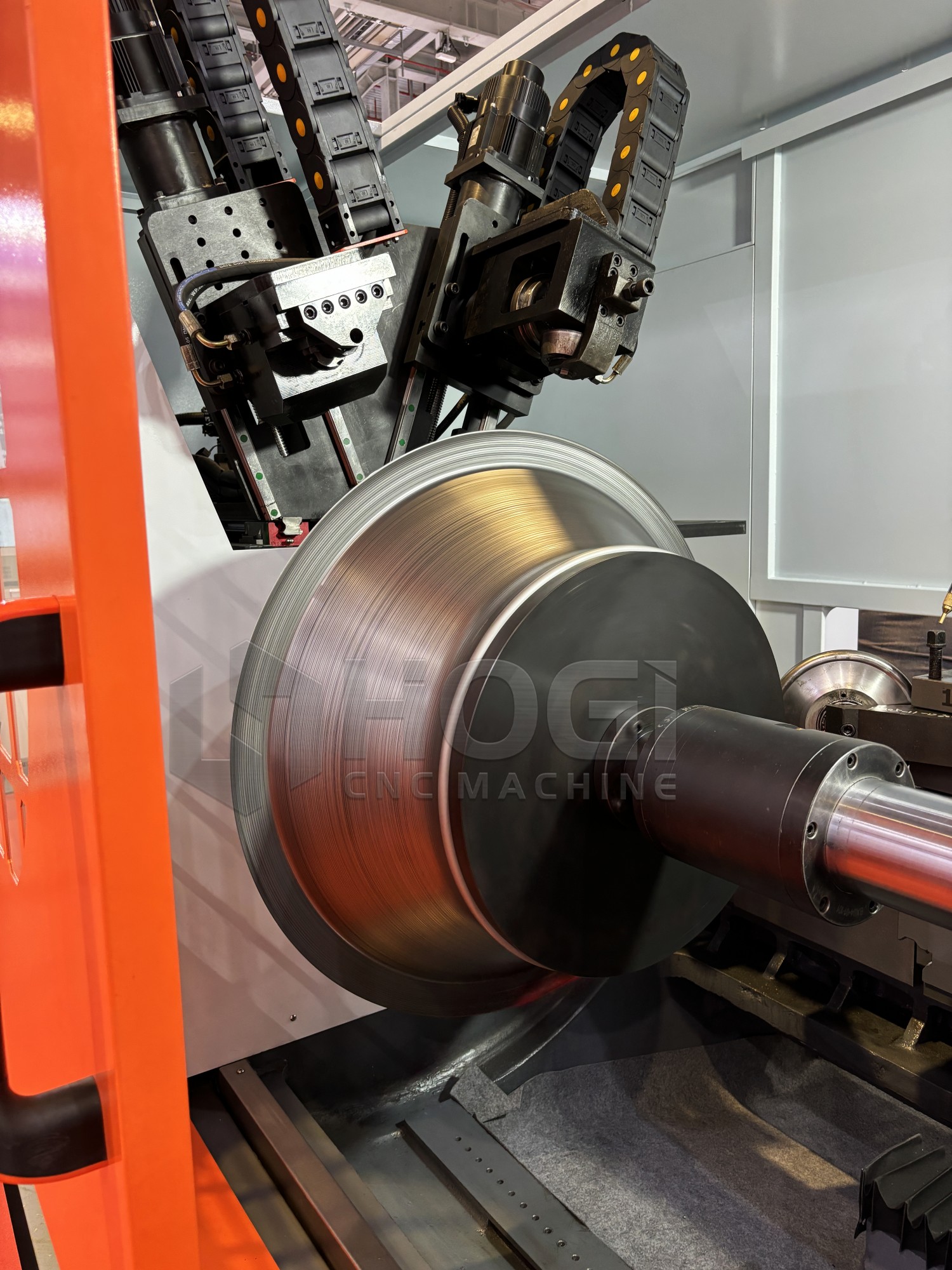

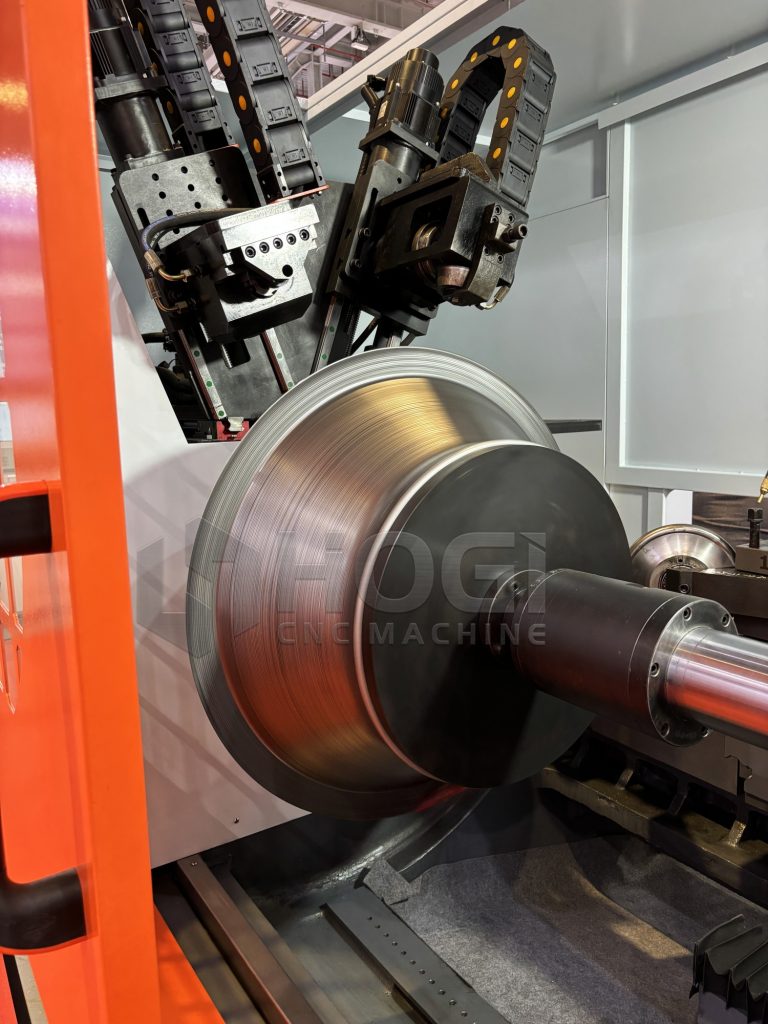

CNC Spinning Machine Series

Machine Name: Automatic Metal CNC Spinning Machine

Model:

Single-wheel CNC spinning machine

Double-wheel CNC spinning machine

Thinning CNC spinning machine

Splitting CNC spinning machine

Neck shrinking CNC spinning machine

Customized spinning equipment

Hub CNC spinning machine

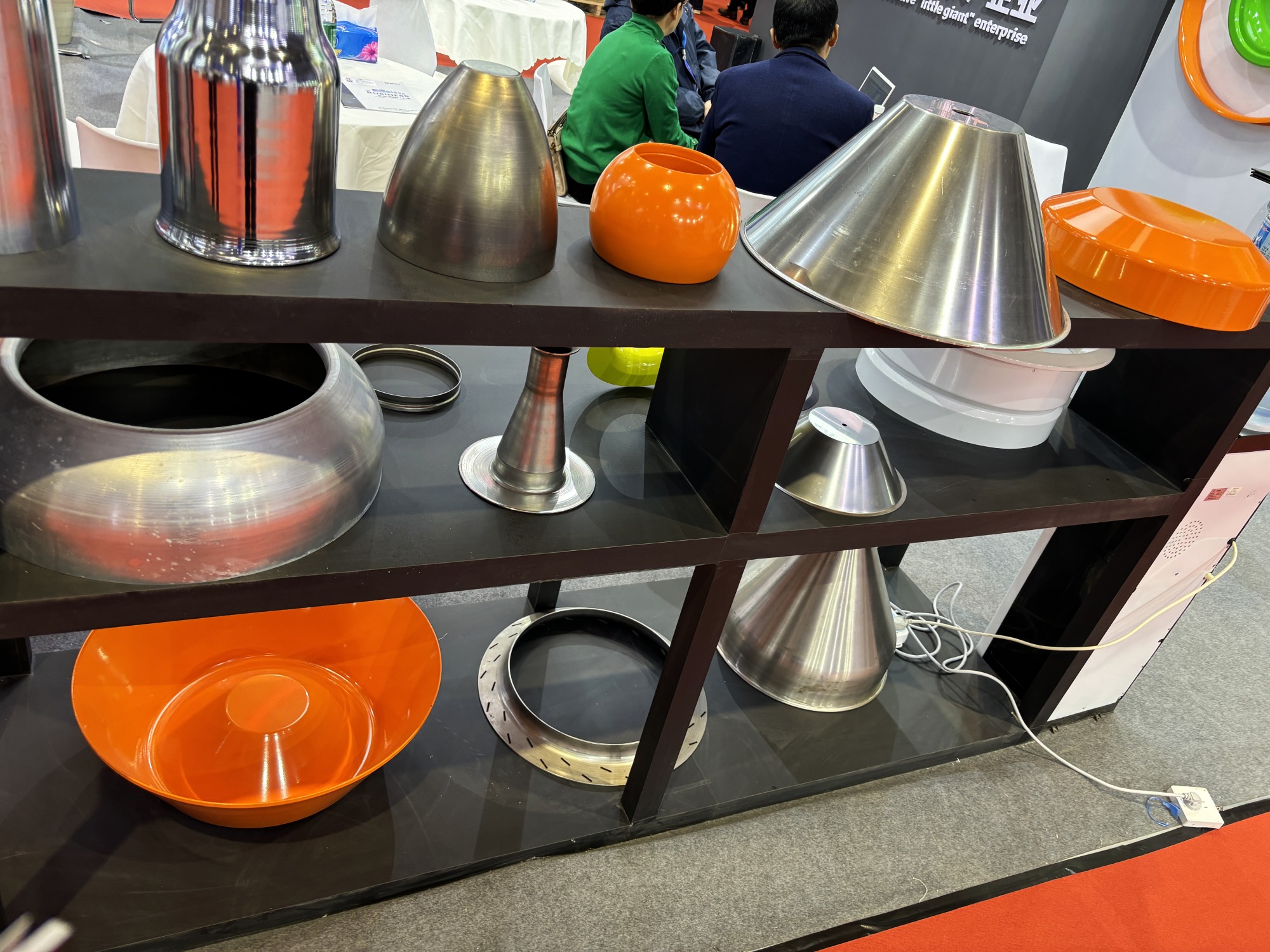

Application Industry: One-time forming, fast production process flow, shortened processing cycle, saving materials and reducing costs are the most ideal choices. They have been widely used in machinery, petrochemical industry, ventilation ring, pressure vessel, automobile industry, electronic appliances, daily hardware, food, military industry and aerospace.

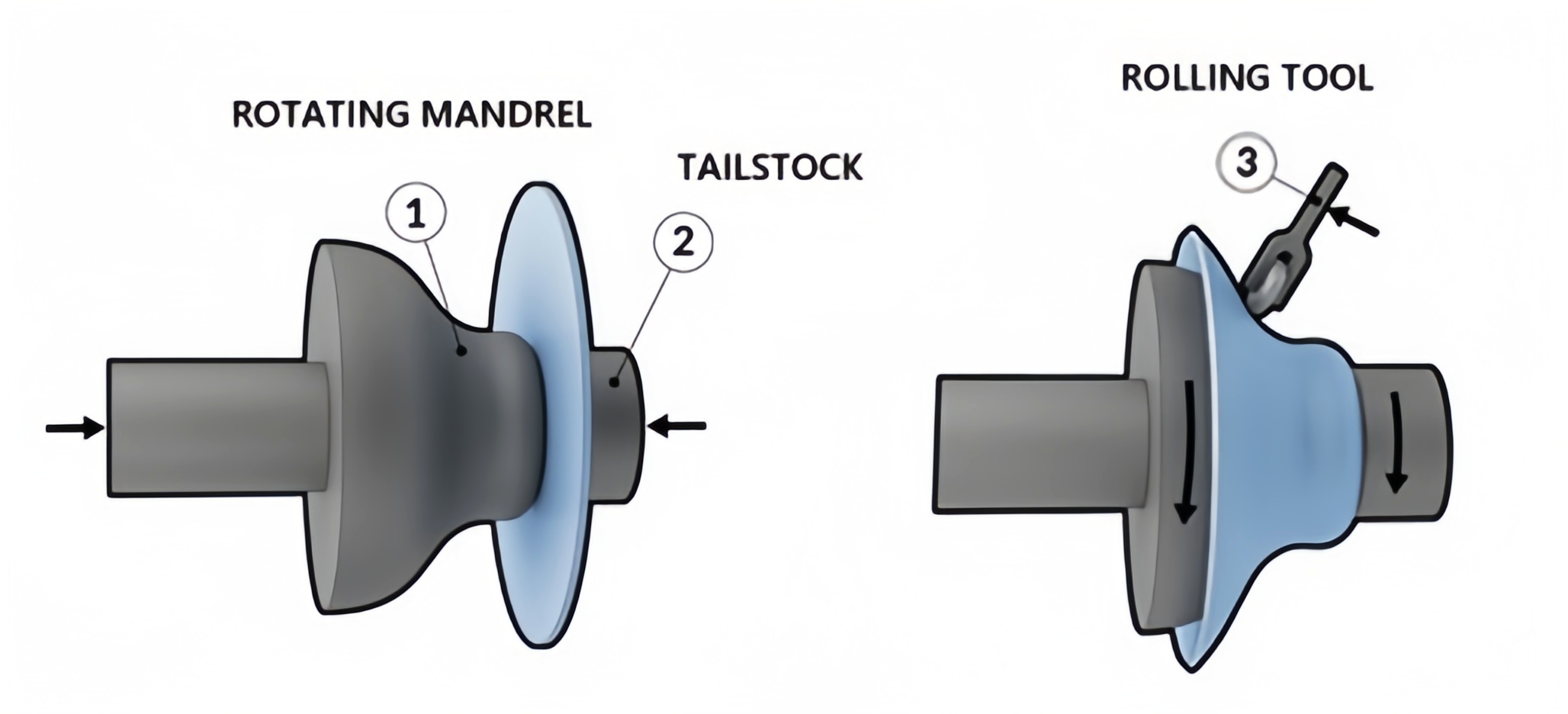

Technical Service: Spinning technology is a plastic forming method for processing metal rotating bodies. It has the characteristics of local continuous plastic deformation. The forming process is to use the rotary wheel tool to make a feed motion and apply pressure to the plate or tube billet rotating along the same axis with the core mold to produce continuous local plastic forming, becoming an advanced forming method for the required hollow rotating parts.

HOGI The main component structure of automatic metal CNC spinning machine

CNC spinning machines are large-scale precision equipment, which are very different in structure and performance compared with other machine tools. CNC spinning machine generally consists of core mold and spindle, spinning wheel and spinning wheel frame, device, tailstock and bed and other major components. Among them, the mandrel and spindle, rotating wheel and rotating wheel frame and rotating wheel control device are called the three main structures of CNC spinning machine.

In order to let the function of the equipment play a full role, to meet the specific requirements of the specific workpiece, CNC spinning machine can also be equipped with related auxiliary facilities. For example, the centering mechanism for mounting carded workpieces, workpiece trimming, crimping device, etc.. If you want to prevent the sheet from wrinkling in the deep drawing and spinning, it can also be equipped with a counter-push roller to gradually deform the sheet. Usually, a complex shape of the workpiece from the installation and positioning of the sheet and spinning forming, and then to the completion of the necessary auxiliary processes, until the workpiece unloading of the whole process can be used in a sequential control. However, CNC spinning machine adopts CNC programming control, which can easily change the process sequence and make the production more flexible.

Application of CNC automatic spinning machine tools HOGI

(1) High machining accuracy. CNC automatic spinning machine tool is given in digital form by the instructions for processing. At present, the pulse equivalent of the spinning machine tool has generally reached 0.001, and the backlash of the feed drive chain and the screw pitch error can be compensated by the numerical control device, therefore, the automatic spinning machine tool can achieve high machining accuracy. For small and medium-sized CNC machine tools, its positioning accuracy generally up to 0.03, repeat positioning accuracy of 0.01.

(2) strong adaptability to the processing object. Automatic spinning machine tool to change the processing of parts, only to re-programming, input new program wheel Guo can achieve the processing of new parts, which is a complex structure of single-piece, small batch production and trial production of new products provides great convenience. For those ordinary manual operation of ordinary machine tools are difficult to process or can not be processed precision complex parts, spinning machine tools can also realize automatic processing.

(3) High degree of automation, low labor intensity. Automatic spinning machine tool parts processing is completed automatically according to the pre-programmed procedures, the operator in addition to placing the perforated belt or operating keyboard, loading and unloading of workpieces, the key process of intermediate inspection and observation of the machine tool operation, there is no need to carry out complex repetitive manual operation, the labor intensity and tension can be greatly reduced, coupled with the spinning machine tool is generally a better safety, automatic chip removal, automatic cooling and automatic lubrication device, the operator’s labor conditions, the operator’s work is not necessary. Lubrication device, the operator’s labor conditions are greatly improved.

(4) High production efficiency. The time required for parts processing mainly includes motorized time and auxiliary time in two parts. CNC automatic spinning machine tool spindle speed and feed changes in the range than ordinary machine tools, so spinning machine tools for each process can choose the most favorable cutting amount. The structural rigidity of the spinning machine allows for powerful cutting with large cutting volumes, which improves cutting efficiency and saves maneuvering time. Since the moving parts of the spinning machine have a high speed of air travel, the clamping time and auxiliary time of the workpiece are less than those of a general machine tool.