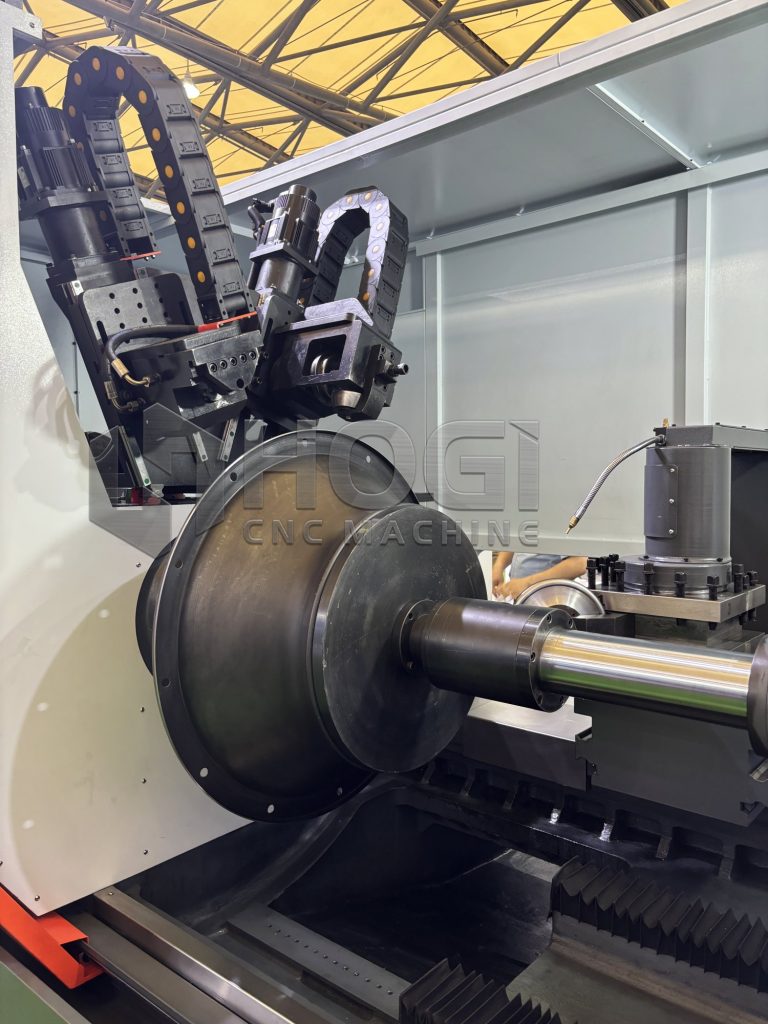

Application and Innovation of CNC Spinning Machines

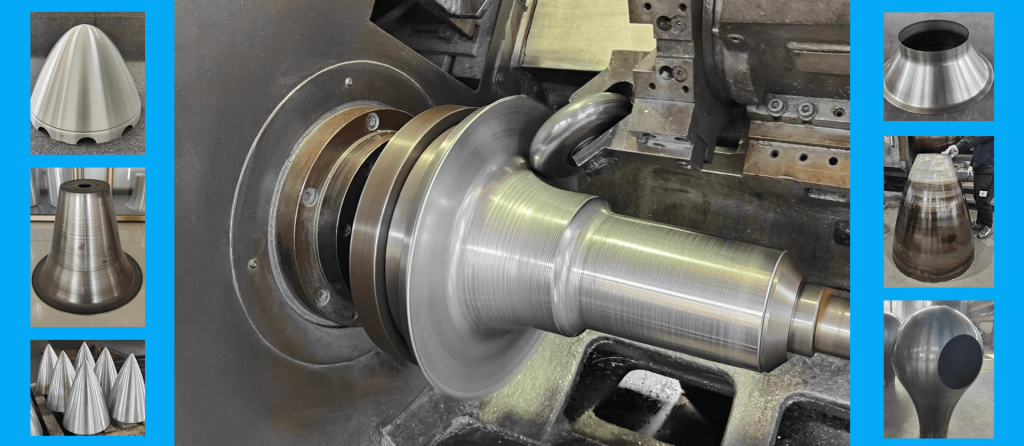

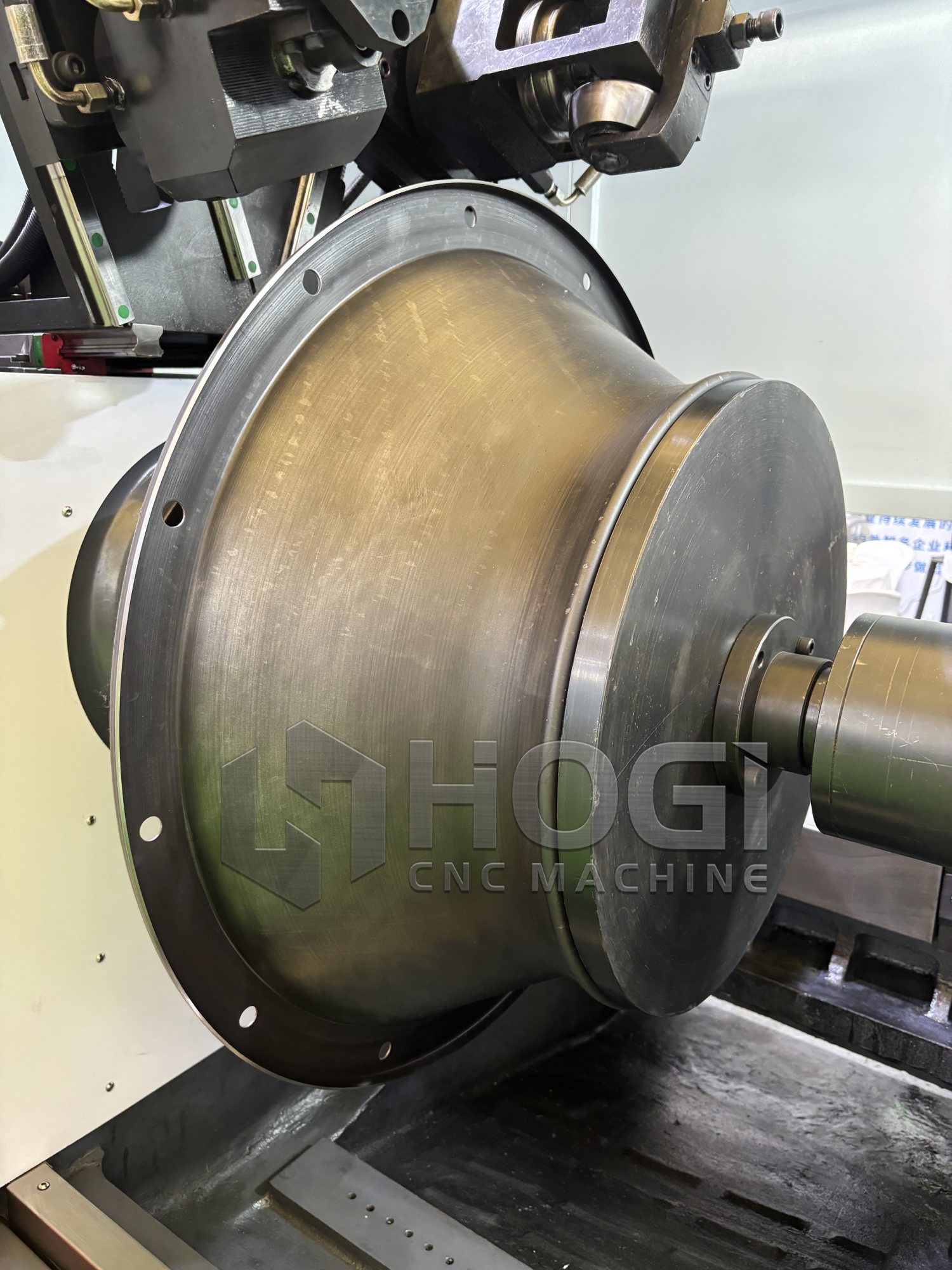

Spin forming belongs to a special way of metal plastic forming, the principle of spin forming is to fix the blank on the mold, the mold and the blank together with the high-speed rotation, the outer spinning wheel on the blank to exert a lot of pressure on the blank, so that the metal blank deformation, and finally shaped with the mold shape of the same parts.

Spinning is divided into ordinary spinning and strong spinning. Ordinary spinning means that the shape of the blank changes during the molding process and the thickness of the blank does not change.

Strong spinning refers to the metal in the forming process not only the shape of the blank changes, the thickness also changes at the same time, generally thinning, in the spinning process of the blank volume remains unchanged, thinning of the blank material to increase the height of the part.

Spinning, an advanced technology that combines the characteristics of multiple processes such as forging, extrusion, stretching, bending, ring rolling, cross rolling and roll extrusion, is known for its unique less-cutting-free processing. During the spinning process, a metal cylinder, flat blank or prefabricated billet is pressed against a spinning mandrel, which is then rotated by a spindle that drives the mandrel and the billet together. At the same time, the spinning wheel, starting from one side of the blank, progressively squeezes the material against the rotating mandrel, thus initiating a point-by-point continuous plastic deformation of the material. This complex series of operations ultimately produces hollow rotating body parts in a variety of busbar shapes.

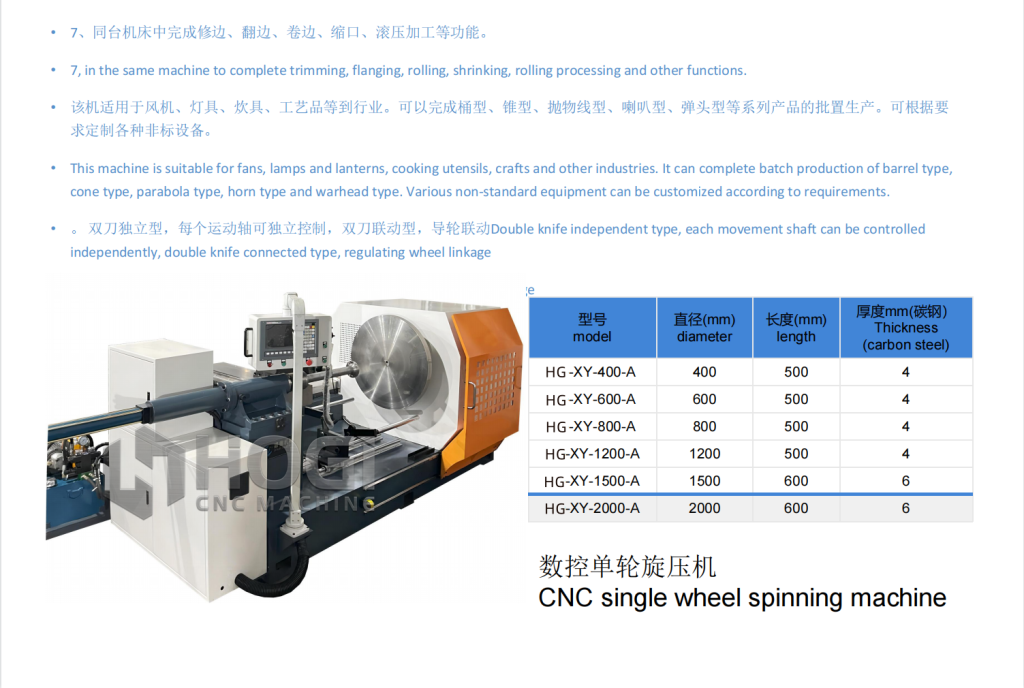

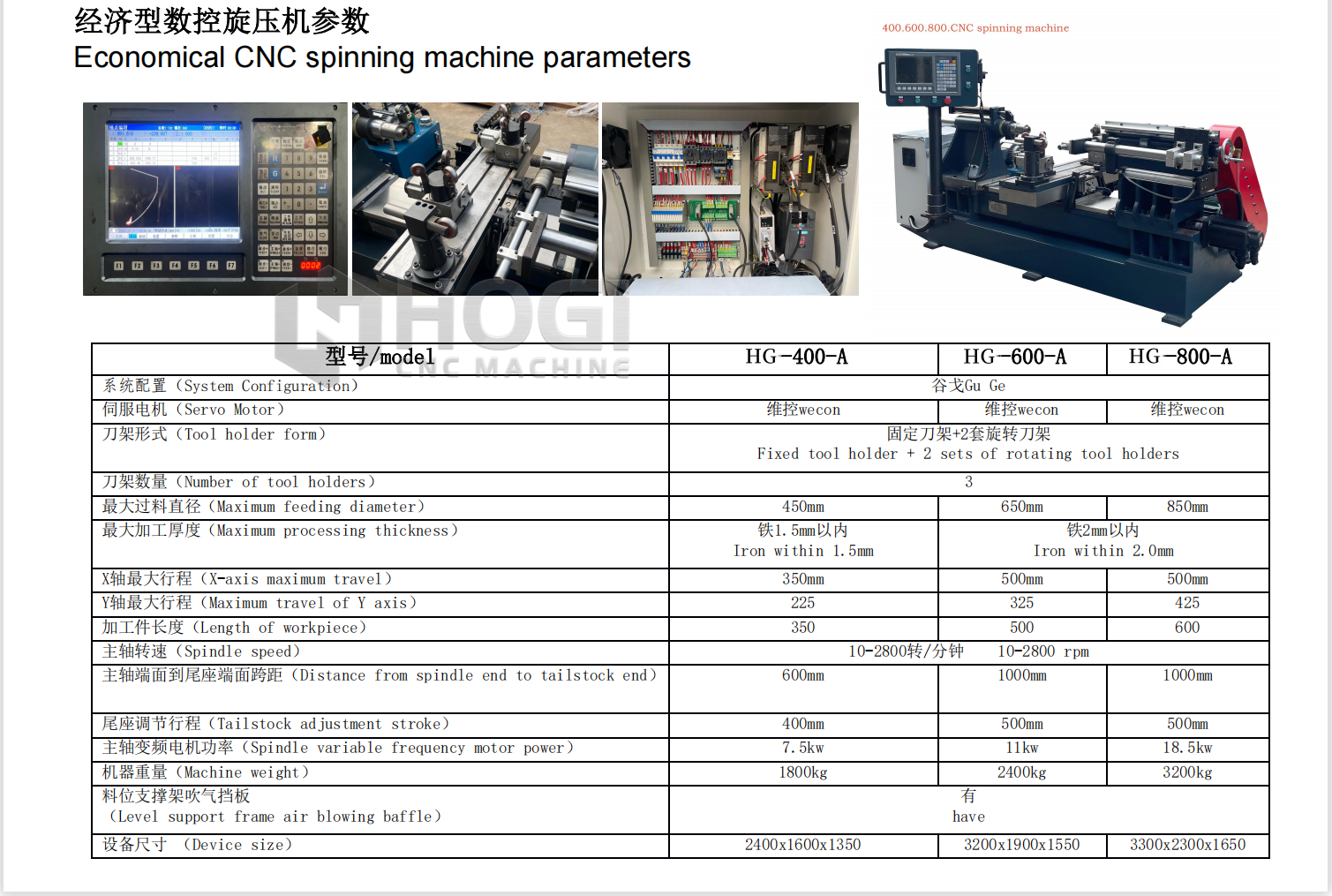

CNC Spinning Machine Series

Single Wheel Spinning Machine

Double Wheel Spinning Machine

Thinning Spinning Machine

Split Spinning Machine

Reduction Spinning Machine

Spinning customized equipment

Wheel Spinning Machine

Provide users with comprehensive and diversified choices and customization!

The wide application of CNC spinning machine is due to its unique processing advantages and features. First of all, CNC spinning machine has high precision and high efficiency processing capability. Through the precise CNC system and advanced processing technology, it can realize the precise processing of complex shapes and curved surfaces, and improve the precision and performance of products. Secondly, CNC spinning machine is characterized by automation and intelligence. Through the integration of advanced sensors and control systems, it can realize the automation and intelligent control of the machining process and improve the production efficiency and product quality. In addition, CNC spinning machine has flexibility and expandability. By replacing different molds and fixtures, it can adapt to the processing needs of parts of different shapes and sizes. At the same time, with the continuous development of technology, the functions and performance of CNC spinning machine are also improving, providing the possibility of application in more fields.

Application of CNC automatic spinning machine tools HOGI

(1) High machining accuracy. CNC automatic spinning machine tool is given in digital form by the instructions for processing. At present, the pulse equivalent of the spinning machine tool has generally reached 0.001, and the backlash of the feed drive chain and the screw pitch error can be compensated by the numerical control device, therefore, the automatic spinning machine tool can achieve high machining accuracy. For small and medium-sized CNC machine tools, its positioning accuracy generally up to 0.03, repeat positioning accuracy of 0.01.

(2) strong adaptability to the processing object. Automatic spinning machine tool to change the processing of parts, only to re-programming, input new program wheel Guo can achieve the processing of new parts, which is a complex structure of single-piece, small batch production and trial production of new products provides great convenience. For those ordinary manual operation of ordinary machine tools are difficult to process or can not be processed precision complex parts, spinning machine tools can also realize automatic processing.

(3) High degree of automation, low labor intensity. Automatic spinning machine tool parts processing is completed automatically according to the pre-programmed procedures, the operator in addition to placing the perforated belt or operating keyboard, loading and unloading of workpieces, the key process of intermediate inspection and observation of the machine tool operation, there is no need to carry out complex repetitive manual operation, the labor intensity and tension can be greatly reduced, coupled with the spinning machine tool is generally a better safety, automatic chip removal, automatic cooling and automatic lubrication device, the operator’s labor conditions, the operator’s work is not necessary. Lubrication device, the operator’s labor conditions are greatly improved.

(4) High production efficiency. The time required for parts processing mainly includes motorized time and auxiliary time in two parts. CNC automatic spinning machine tool spindle speed and feed changes in the range than ordinary machine tools, so spinning machine tools for each process can choose the most favorable cutting amount. The structural rigidity of the spinning machine allows for powerful cutting with large cutting volumes, which improves cutting efficiency and saves maneuvering time. Since the moving parts of the spinning machine have a high speed of air travel, the clamping time and auxiliary time of the workpiece are less than those of a general machine tool.