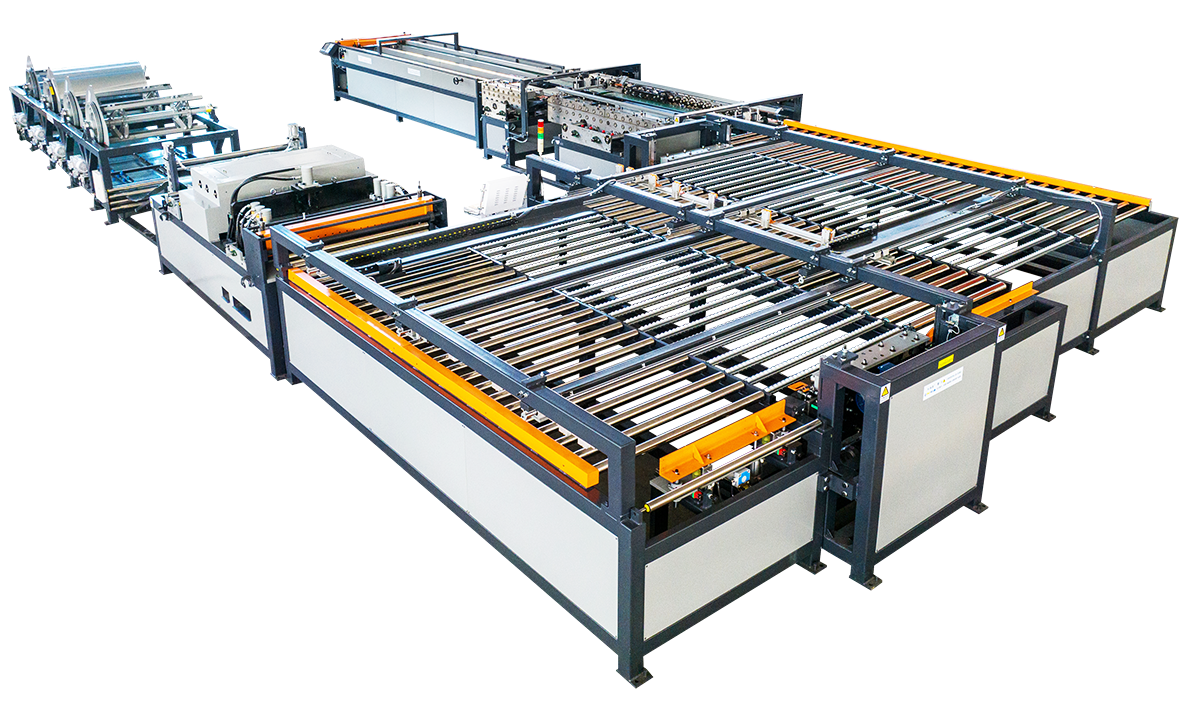

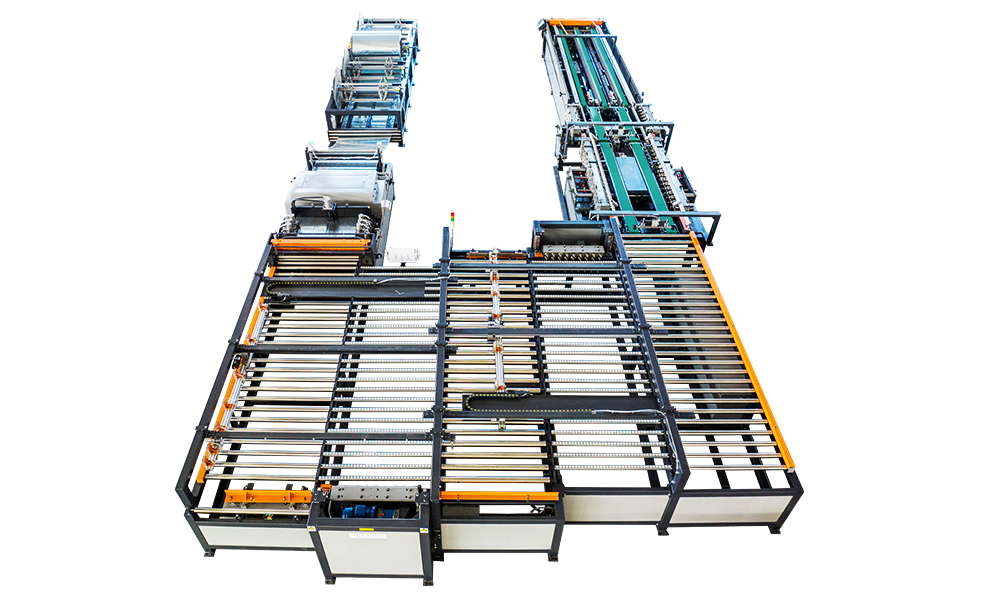

Automatic air duct production line configuration and function details

Machine Name:Automatic air duct production line

Model:Fully automatic air duct production 2 3 4 5 6 7 line. U-type air duct five lines

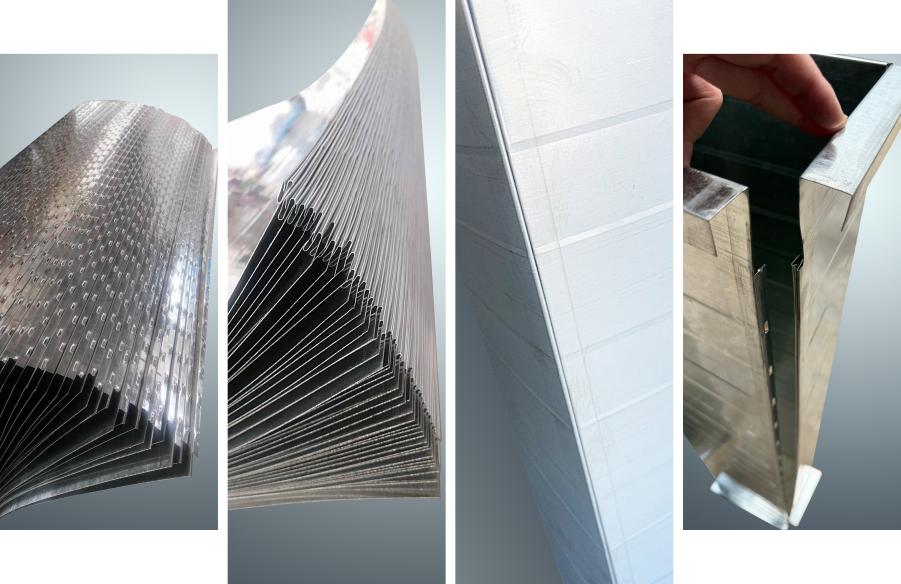

Application Industry:The fully automatic air duct production line is mainly used in engineering fields such as ventilation, air conditioning, and purification. In the field of ventilation, the production line can be used to produce various ventilation equipment, such as centrifugal fans, axial flow fans, filters, etc. In the field of air conditioning, the production line can be used to produce various air conditioning terminal equipment.

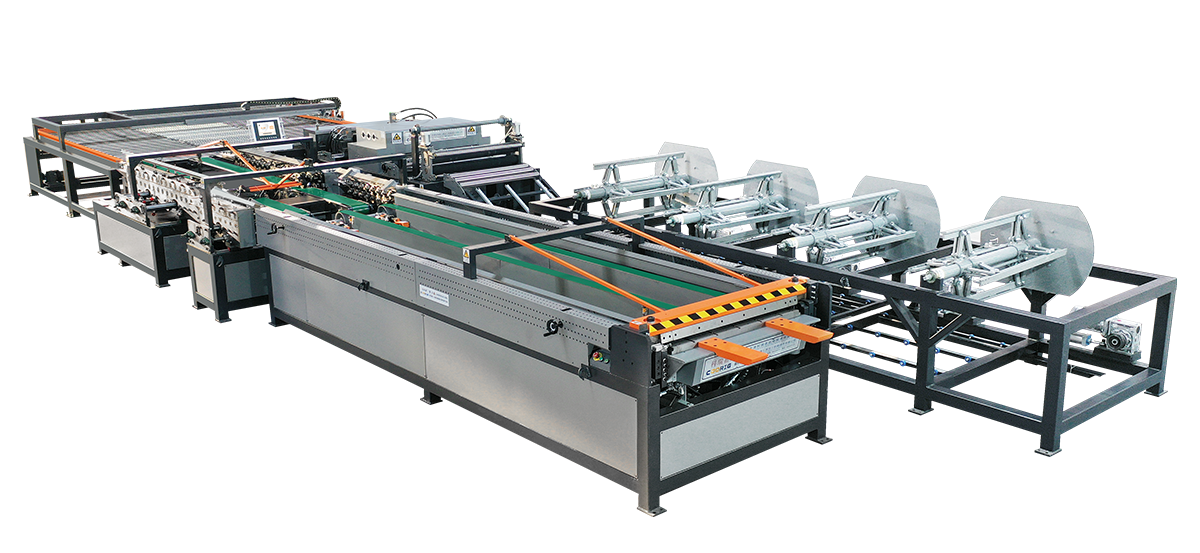

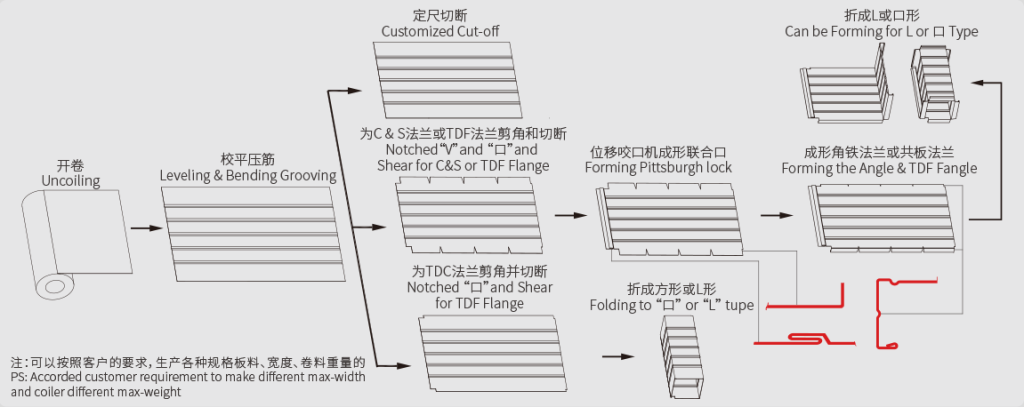

Technical Service:The fully automatic duct production line integrates multiple functions such as uncoiling, leveling, rib pressing, corner punching, shearing, high-speed joint biting, angle steel flange forming, common plate flange forming and folding forming, realizing the automation of duct production.

HOGI automatic air duct production line integrates the functions of uncoiling, leveling, rib pressing, corner punching, shearing, high-speed joint nibbling, angle steel flange forming, common plate flange forming and bending square forming to realize the automation of air duct production.

Product Features:

Precision manufacturing capability: Using high-level processing equipment and cutting-edge manufacturing technology to ensure that the dimensional accuracy and appearance quality of the air ducts reach the highest level in the industry.

Fully automated production process: From the addition of materials to the output of the bottom line, the entire process is fully automated, reducing manual participation and improving production efficiency and consistency.

Diversity of specifications: Supports the production of various types of air ducts, including rectangular, circular and special-shaped air ducts, which can meet the specific needs of various customers.

Energy-saving and environmentally friendly design: The use of energy-saving equipment and processes reduces energy consumption and emissions, and meets environmental protection requirements.

Intelligent management system: Equipped with an intelligent production management platform, it realizes real-time monitoring and analysis of production data, providing a decision-making basis for the optimization of production processes.

HOGI focuses on the research and development and sales of fully automatic duct production lines, and also provides a variety of duct processing machinery and equipment. Its product line covers linear duct fully automatic production lines, as well as common plate flange forming machines, common plate flange folding machines, vertical joint machines, laser cutting machines and other multifunctional equipment. These products are not only comprehensive in function, but also easy to operate, providing efficient and reliable solutions for duct processing companies.

1. The fully automatic duct production line integrates unwinding, leveling, rib pressing, corner punching, shearing, high-speed joint bite, angle steel flange forming, common plate flange forming and folding forming, realizing the automation of duct production.

1. The fully automatic duct production line only requires 1-2 workers to operate, and the daily output can reach about 1,500 square meters, which greatly improves production efficiency.

2. The production line uses an independent motor to drive the material roll, ensuring the accuracy and efficiency of processing.

3. The unique material saving mode makes each roll of material only produce less than 20mm of waste, effectively saving raw materials.

4. The folding servo feeding system has accurate positioning, especially when processing “mouth”-shaped pipes, its advantages are more significant.

5. The touch screen input mode simplifies the operation process and enhances the stability of operation.

6. The production line has production management functions, including cumulative counting, which is convenient for real-time monitoring of production conditions.

7. The linear structure makes the production process smoother, occupies a small area, reduces the transmission time of the sheet material, and further improves production efficiency.

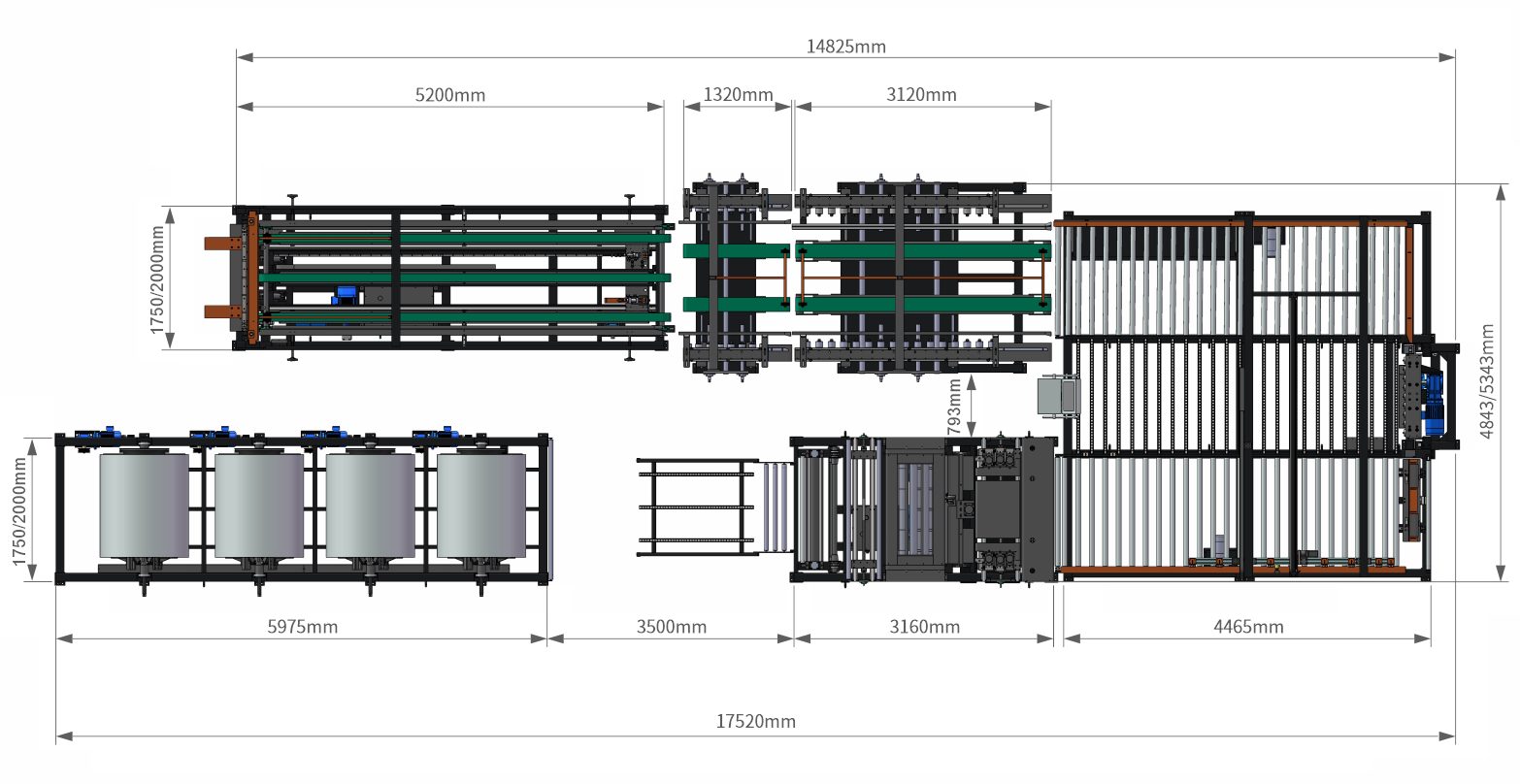

8. To ensure the smooth progress of production, the workshop operation site is recommended to be at least 30 meters long and 10 meters wide, and equipped with a workshop or site for storing formed pipes.

U-shaped fully automatic duct production line structure