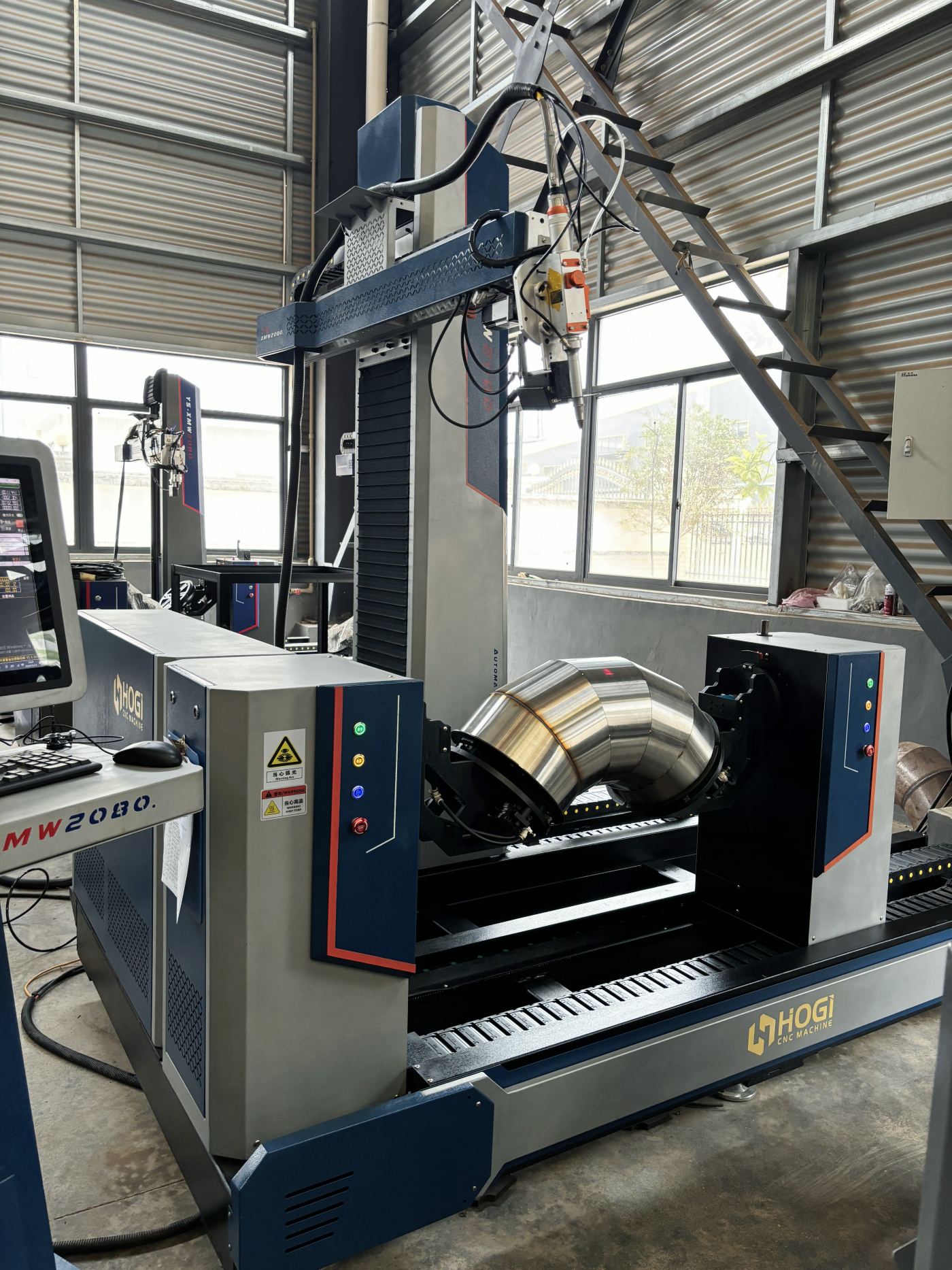

HOGI Shrimp elbow pipe duct automatic welding machine

Machine Name: Shrimp elbow duct automatic seam welding machine

Model:

Workpiece Diameter:Elbow pipeΦ200~Φ800mm

Number of workpiece sections: 3-9 elbows

Workpiece wall thickness: 0.5 to 3mm (stainlesssteel)

Application Industry: Industrial ventilation fan HVAC engineering complete welding equipment.

Technical Service: Elbow duct welding is an automatic welding for shrimp elbow butt joints. It realizes visual program setting. The system adopts input welding method to set the diameter and number of sections of the pipe elbow for welding. The weldable materials include carbon steel and stainless steel. MAG welding and laser welding can be selected. The equipment has a reasonable structure, convenient operation, advanced technology, and uses touch screen and PLC program control, and is equipped with an intelligent detection system to achieve welding of elbows in all positions. The modular design can be quickly and easily combined into the required welding system according to customer requirements. The equipment comes with a 3-9 section elbow assembly graphic system, which can set the number of elbow sections and angles by itself. The whole system adopts a weld correction system, and there is no need for programming to accurately position the welding.

HOGI Elbow pipe duct Automatic seam welding machine

The workpiece is pre-spot welded and assembled, placed on the welding fixture, and adjusted to the corresponding position by controlling the equipment fixture, and the expansion fixture is started to position the workpiece.

Set the movement speed and direction of the machine head and the appropriate welding parameters.

The entire welding specification and welding process parameters must be determined after the test welding of a certain workpiece, and the final welding parameters must be determined after the various parameters are corrected.

Including: welding speed, welding voltage, welding current, wire diameter selection, etc.

Using computer full digital control technology, all welding parameters are digitally displayed and can be pre-set, the operation is flexible and convenient, and the control station has a linkage interface that can be linked with other products of the company.

This system consists of an industrial control computer center, a visual sensor system, a 5-axis manipulator, a dual-drive fixture, a welding power supply, etc.

The full digital control system composed of an industrial computer is used to control the welding power supply, welding head, electric fixture, and welding manipulator. The information exchange between each single machine uses communication technology. The input of parameters and commands is concentrated on the control screen, which can be moved and operated, and has parameter preset and digital display functions.

The heavy-duty shrimp bend automatic welding system consists of 6-axis welding robot, Positioner, Walking rail, weld scanning system, heavy-duty fixture, Control system, and Welding power supply.

Upgraded version of shrimp elbow automatic welding – robot shrimp elbow automatic welding, using vertical welding process, to obtain beautiful welds, the equipment can monitor the operation process in real time during operation, the welds are tracked by laser scanning, and many welding process parameters can be set on the touch screen. The equipment operation platform has buttons such as start, stop, and emergency stop.

Heavy shrimp elbow automatic welding consists of a 6-axis welding robot, a positioner, a walking ground rail, a weld scanning system, a heavy fixture, a control system, and a welding power supply. It is used to replace manual automatic welding of shrimp elbows. No manual intervention is required during the welding process. Manual operation only requires loading before welding and unloading after welding. Based on graphic parameter settings, laser scanning real-time modeling, fitting welds to meet the correction requirements of irregular products, the product is simple to operate and easy to use. Reduce the steps of weld simulation operation. Improve efficiency.