Multi-function flanging machine equipment HOGI company design and development, production for a variety of large industrial fans, ventilation ducts, air valves, vibrating screens, pressure vessels and other sheet metal parts forming pipeline flanging machines and equipment, this product features: easy to operate, flanging speed, punching precision, flanging width, flanging the diameter of the duct, length and punching the number of holes and the size of the shape can be adjusted, and other advantages.

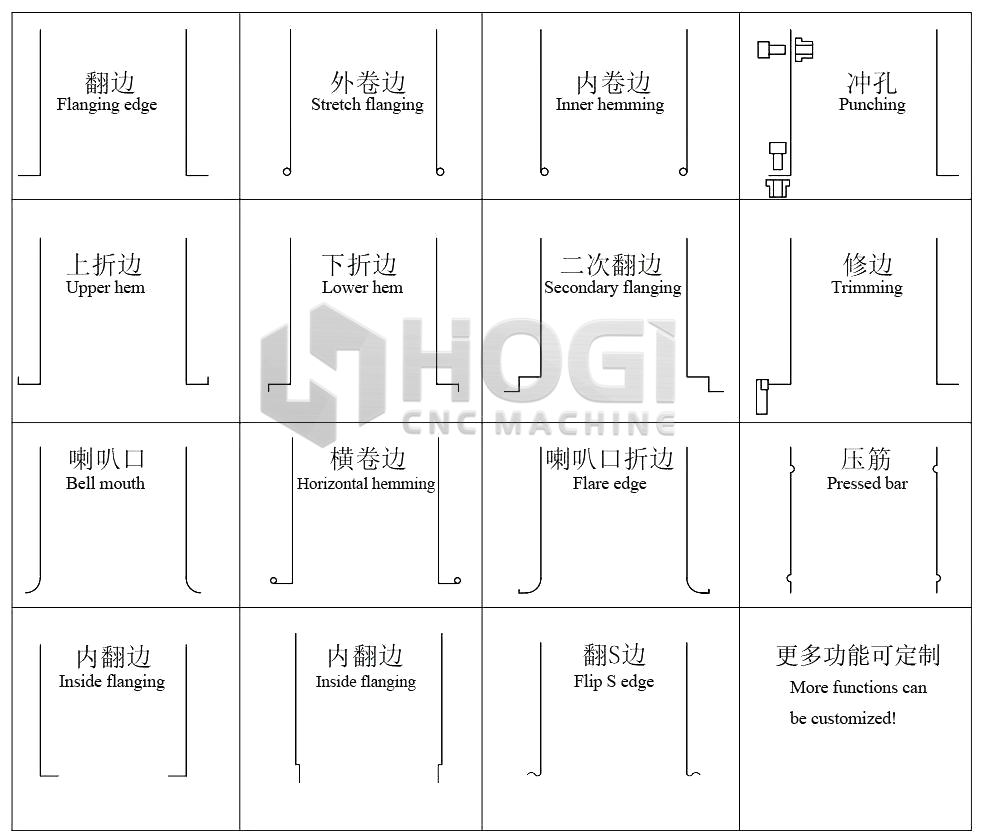

Can be added according to requirements of straight edge, rolled edge, flared edge, pressure tendons, pressure groove, trimming, flaring, shrinking, secondary folding, upper and lower folding, punching and other functions; can be customized according to customer requirements of various equipment.

CNC flanging machine equipment features.

The equipment CNC control, through the preparation of different programs, can complete the flanging work of flare, straight edge, 0-90 degrees of any straight and oblique edges, when replacing the workpiece molds, only need to call out the program. Punching function with high precision, can complete 0-100 holes arbitrary punching.

Equipment Advantages.

1. Double servo motors, punching accuracy is not affected by gear wear.

2. each group of base rail only need to loosen the screws to adjust the different workpieces, convenient and quick, but also can add servo motors, fully CNC adjustable workpieces of different diameters.

3. the machine parts do black treatment, beautiful, durable, not rust. The panel does special anti-rust treatment, beautiful and wear-resistant.

4. thick material, solid structure, absolutely no solidity problems.

5. The quality is guaranteed by many inspections during the production of the machine.

Multi-function flanging machine forming workpiece

Our machines can be customized with any of the features in the above list, up to 4 groups of features per machine.

Regular diameter specifications include 150-800mm, 200-1300mm, 250-1600mm, 350-2000mm, and 400-2500mm, while regular options for thickness are 0.6-4mm and 2-6mm. if customers need other specifications for diameter and thickness, we can also customize them according to their requirements.

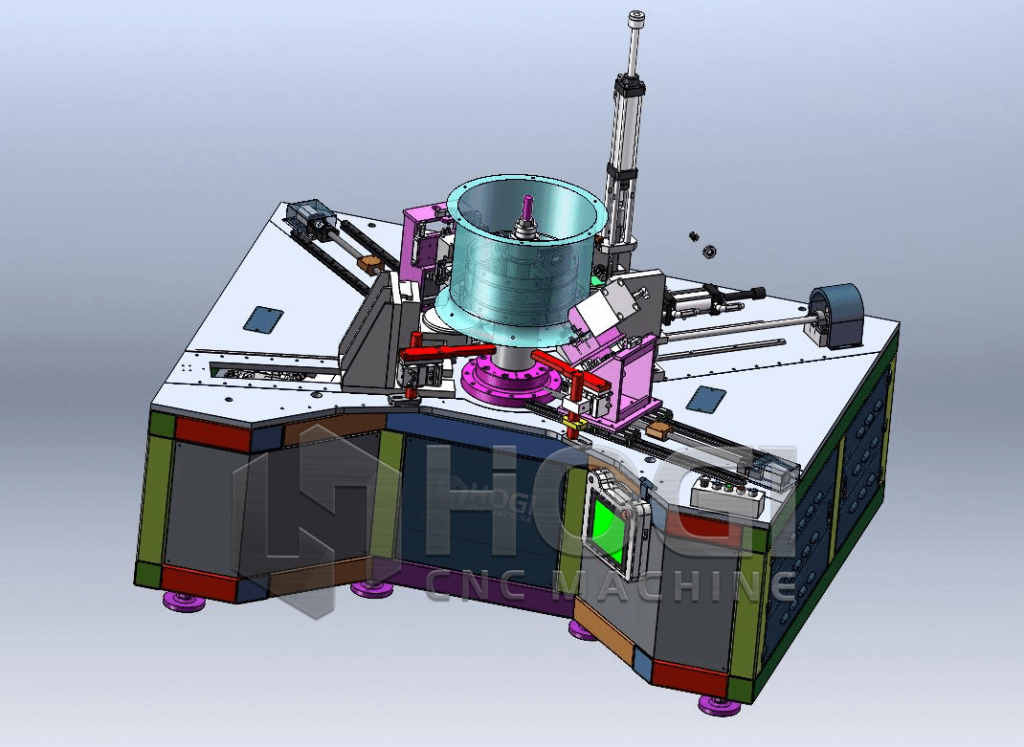

AUTOMATIC FLANGING MACHINE

Model 1300type: Multi-function flanging, punching, crimping and flaring.

The equipment non-standard customized models. Come to the drawing according to the requirements of drawing design customized, if other specifications can also be customized!

The equipment flanging diameter 300-1300MM. Thickness of flanging 0.8-4MM Flanging width 10-50MM

The function of the equipment: turning straight edge, punching, crimping, flaring, one-time forming.

The performance of the equipment: good stability, one time to complete the process, can be manually adjusted, automatic mass production.

Multi-functional automatic flanging machine for fans Flanging, punching, crimping, reinforcement:

This equipment is a non-standard customized equipment, the main function is to turn the straight edge, punching, crimping, reinforcing bars.

The machine can process diameter 350-1600MM height 100-1500MM thickness 0.8-4MM.

The equipment contains automatic flattening function, automatic flanging, punching, crimping and reinforcing, only manual loading and unloading.

CNC flanging 1600 type large horn horizontal and vertical rolled edge automatic flanging machine

Large diameter industrial fan pipe flanging machine 3000 type flanging punching forming

Equipment Features:

- servo drive each motion axis, high positioning accuracy, stable size

- CNC system control, through the preparation of the program, can be flanging various sizes of flares

- program with save function, replace the workpiece only need to change the mold, call up the molding can be

- One-key operation, can easily complete the lower crimping, upper flare crimping process.

Customized non-standard metal forming equipment:

It refers to the product of non-standardized molding equipment that is designed and manufactured according to the specific needs and requirements of customers to meet their individual requirements.

The design and manufacture of our customized non-standard molding equipment series requires a full understanding of the customer’s specific needs and requirements, including the shape, size, material, process and other aspects of the product. Our designers will work with the customer to understand their production process and the limitations of their existing equipment in order to provide them with the best solution.

The advantage of the customized off-standard molding equipment series is that it can meet the customer’s individual needs and improve production efficiency and product quality. Through customized design, the equipment can be more adapted to the customer’s production process, increasing productivity and capacity. In addition, the Custom Molding Equipment line can be optimized for customer-specific product requirements, improving product quality and consistency.