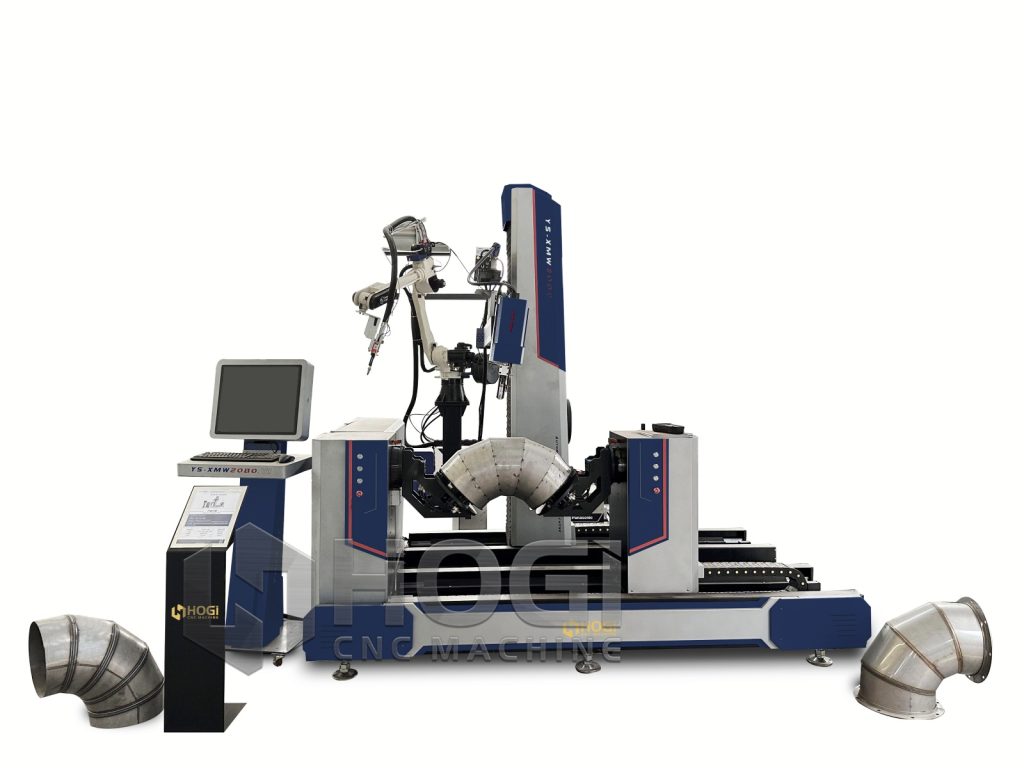

This equipment is for shrimp elbow butt automatic welding, the realization of the visualization of the program settings, the system adopts the input welding method, set the pipe elbow diameter and the number of sections to weld, can be welded materials such as carbon steel, stainless steel, can be selected from the TIG and MAG. laser welding, the equipment has a reasonable structure, easy to operate, advanced technology, the use of touch-screen and Plc programmable control, together with an intelligent detection system, can achieve all-position elbow welding. It can realize all-position elbow welding. Modular design, according to customer requirements can be quickly and easily combined into the required welding system; equipment comes with 4-9 sections of elbow assembly graphics system, self-setting elbow section and angle, the whole system adopts the seam tracking and deviation correction system, no need to program the precise positioning of welding.

●Applicable to ring seam welding of elbow spliced workpieces;

●MAG/MIG/TIG/Laser welding process can be selected according to the welding process.

●Can weld mild steel, stainless steel, and other materials.

●Can weld flat and lap joints of tubes.

●Can be equipped with pneumatic loading, pneumatic tightening and other jigs and fixtures according to the characteristics of the products.

***Adaptation of workpieces:

| Workpiece Material | Austenitic stainless steel |

| Welding Requirement | TIG Welding (TIG) |

| Workpiece Size | Workpiece Diameter: Elbow pipe Φ200~Φ800mm Number of workpiece sections: Verses 3-9 Workpiece wall thickness: Δ1.0 to 3mm (stainless steel) Workpiece weight: M < 0.6T |

| Weld form | Cylinder/cylinder straight seam butt joints |

| Work environment | Temperature range: -10 to 50°C Relative humidity: ≤75% (long-term), 90% (short-term, no condensation) Grid fluctuation: ±10% Altitude: below 1000m |

Shrimp elbow automatic welding upgraded model – robot shrimp elbow automatic welding, using vertical welding process, to obtain beautifully shaped weld, equipment in the process of operation can be real-time monitoring of the operating process, the weld is tracked by laser scanning, in addition to the touch screen can be set up in a number of welding process parameters. There are buttons for start, stop and emergency stop on the operating platform.

Heavy duty shrimp elbow automatic welding consists of 6-axis welding robot, shifter, traveling ground rail, weld scanning system, heavy duty fixture, control system, welding power supply. It is used to replace the manual to complete the automated welding of shrimp bends, the welding process does not require manual intervention, the manual operation is only required to load the material before welding and unload the material after welding. Adopt graphic parameter setting as the basis, laser scanning real-time modeling, fitting the weld to achieve the irregular products of the corrective requirements of the product, the product is simple to operate, easy to use. Reduced weld channel simulation running steps.

General scheme of the control system:

1.1 Overall arrangement:

The system consists of industrial control computer center, Japanese vision scanning sensing system, 5-axis manipulator, double-drive fixture, welding power supply and so on.

1.2 Electrical control system:

Using industrial control machine composed of all-digital control system, the welding power supply, welding head, electric fixture, welding machinery hands control, the exchange of information between the single machine using communication technology, parameters and commands input centralized in the control screen, can be moved to operate, and has a parameter preset and digital display function.

1.3 The control system will have the following basic functions:

* The system has the functions of over-current, over-voltage, under-voltage and emergency stop.

*The system has protection measures for personal safety and equipment safety to ensure safe production.

*Part of the control box and operation panel with emergency stop button.

Adopting computerized all-digital control technology, all welding parameters are digitally displayed and can be pre-set, flexible and convenient operation.

The control station leaves a linkage interface to realize linkage with other products of our company.

***Welding process

The automatic welding machine according to the different welding processes used can be equipped with melting electrode gas shielding welding, tungsten argon arc, such as welding process or a variety of welding processes to achieve the automatic welding of the elbow.

Argon arc welding process and gas shielding welding process used in the field.

□ Argon arc (TIG/hot wire TIG)

□ Gas-shielded (MIG/MAG process)

□Argon arc + gas shielding (TIG/hot wire TIG + MIG/MAG)

***Welding quality

*The bottoming welding can realize one-side welding and two-side molding and weld height control;

*To meet the ray detection, ultrasonic testing Ⅰ or Ⅱ level of weld qualification rate of 98% or more;

*Meet the requirements of pressure test or impact, tensile, bending and other mechanical properties test.

*Angle welding to meet the welding angle height and pressure test requirements.