4 Roll Plate Bending Machine

The 4 Roll Plate Bending Machine is an extraordinarily superior and green answer used within the metalworking enterprise for shaping plates into cylindrical or conical forms. Unlike conventional bending machines, this version offers extra precision, decreased managing time, and advanced manipulation over the bending method. Its layout lets in operators to achieve correct pre-bending and rolling in a single setup, making it a desired choice for industries that demand velocity, reliability, and consistent niceness.

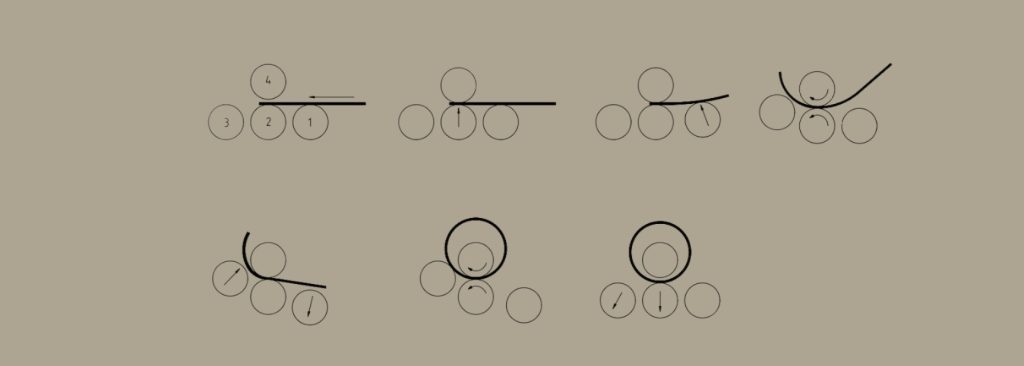

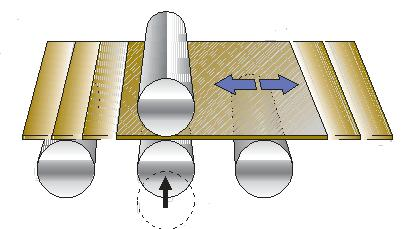

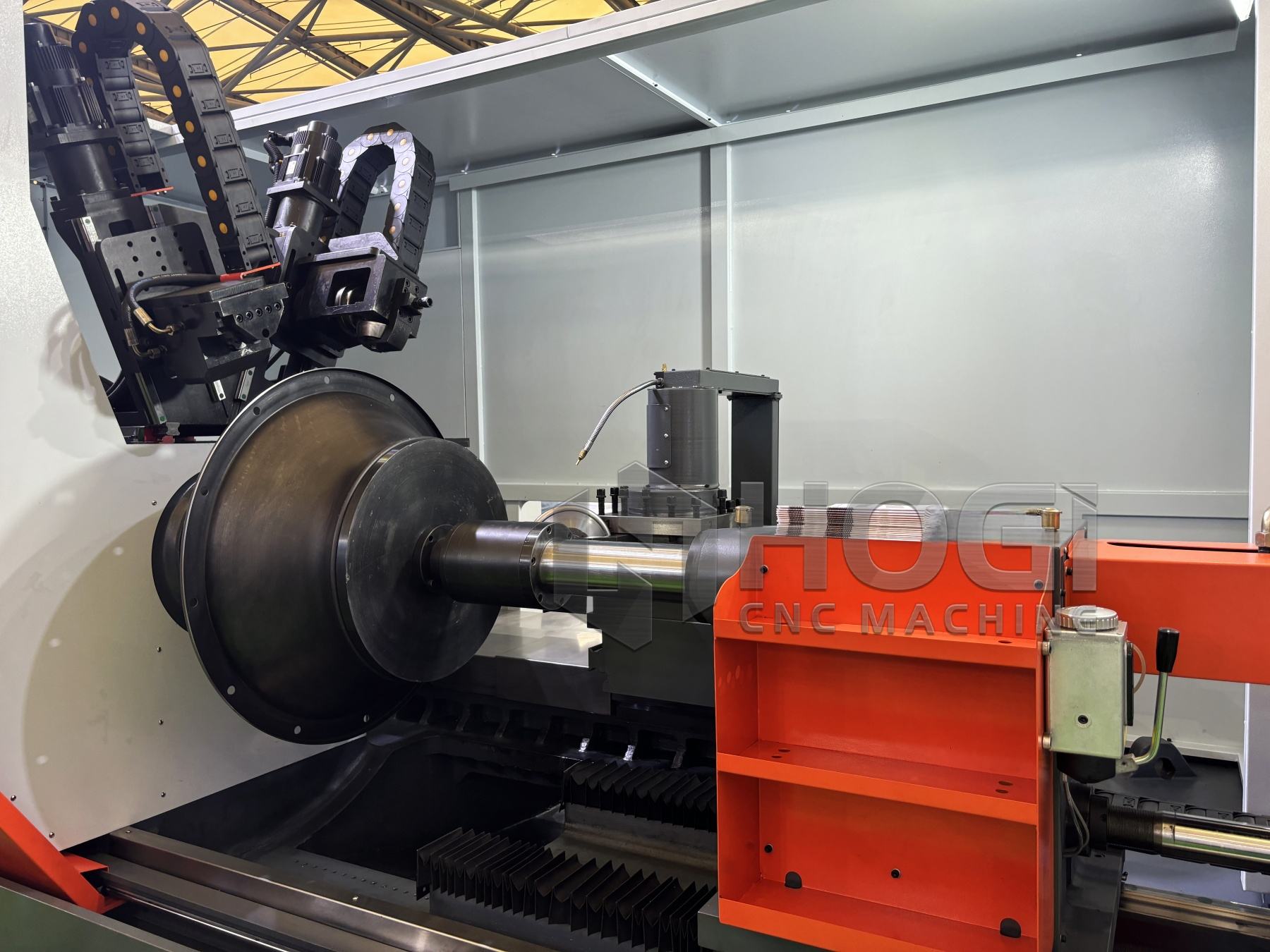

Operating Mechanism Of The System

The 4 Roll Plate Bending Machine in China operates with 4 rollers strategically placed to facilitate seamless bending. The top roll typically acts because the primary using roll, whilst the decrease roll helps the fabric. The 2 facet rolls are placed to press in opposition to the plate, making sure accurate curvature and decreasing the hazard of fabric slippage. This configuration lets the operator carry out pre-bending at each end of the plate without getting rid of and repositioning it, which significantly improves workflow efficiency.

3-6m/min

Rolling Speed

245Mpa

Plate yield limit

Benefits Of The Usage Of A 4 Roll Bending Gadget

One of the important strengths of this gadget is its potential to address complex bending operations with minimum manual intervention. The automation capabilities permit for steady effects even when coping with thicker or larger plates. The Machine guarantees that the material stays securely in the area in the course of the complete technique, which now not only enhances precision but also reduces the likelihood of mistakes. Additionally, the potential to carry out pre-bending and final rolling in one cycle drastically saves time and labor costs for manufacturers.

Applications in Different Industries

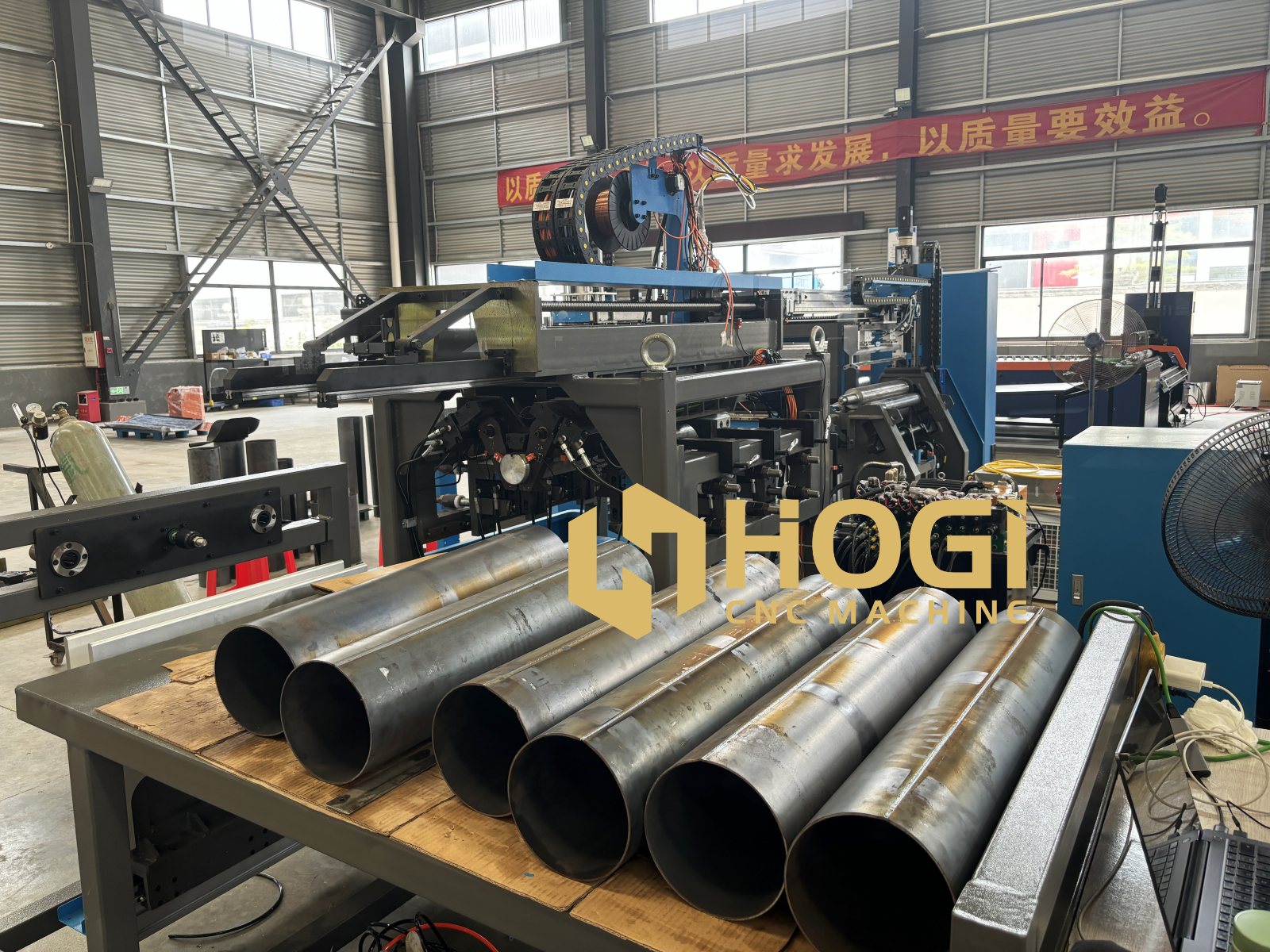

The 4 Roll Plate Bending Machine Supplier in China unearths programs across a wide variety of industries. It is broadly used in the manufacturing of strain vessels, boilers, tanks, wind towers, pipelines, and different cylindrical systems that require precise shaping. The shipbuilding industry also advantages from its skills, as huge metal sheets may be formed into precise shapes for hulls and structural components. Strength, construction, and heavy equipment manufacturers an increasing number of depend on this gadget for his or her large-scale metallic forming desires.

Automation and Modern Features

4 Roll Plate Bending Machines are frequently integrated with CNC controls that allow operators to program bending sequences for more accuracy and repeatability. Those superior structures lessen dependency on manual ability and make the gadget greater versatile. A few models additionally function digital presentations, hydraulic changes, and automated feeding structures that simplify operations and similarly raise productiveness. This degree of automation no longer only complements output but additionally ensures that protection standards are maintained in the course of excessive-ability operations.

Durability and Efficiency

Built with sturdy substances and designed for heavy-duty use, the 4 Roll Plate Bending Machine China is thought for its sturdiness and lengthy operational existence. Manufacturers awareness on engineering machines that can resist the trials of non-stop manufacturing. Performance is performed not only thru the mechanical layout but also thru consumer-pleasant interfaces and automatic aid structures. The reduced need for remodel and improved coping with large plates upload to the general performance of the production procedure.

About 4 Roll Plate Bending Machine

The 4 Roll Plate Bending Machine Manufacturer in China has emerged as an imperative tool in modern manufacturing, presenting unequalled precision, reliability, and simplicity of use. Its capability to streamline bending operations, combined with its adaptability to various industrial requirements, makes it a critical investment for businesses focused on exceptional overall performance. As industries continue to conform, the demand for advanced metal forming solutions similar to the 4 roll plate bending gadget will continue to grow.

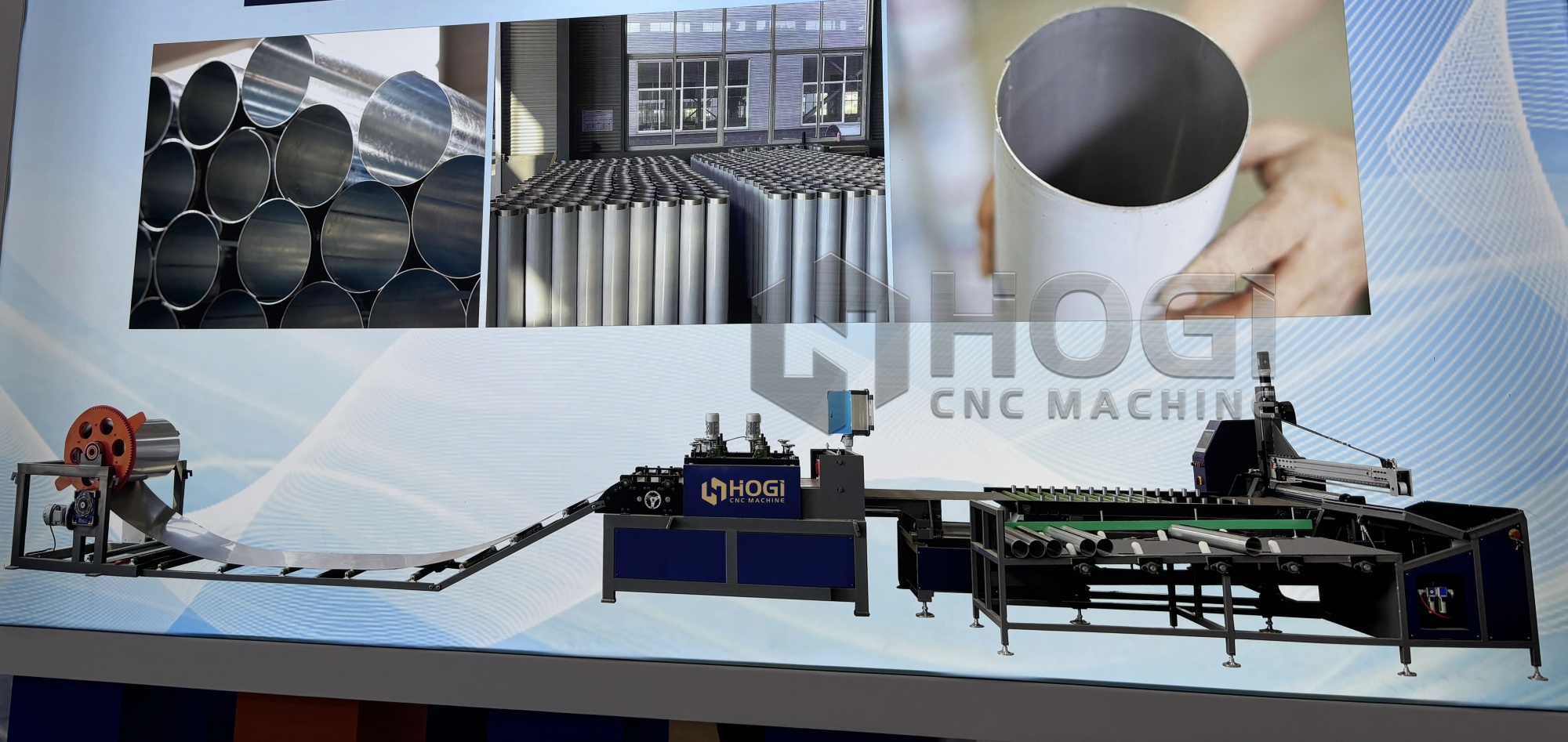

Why HOGI CNC

HOGI CNC machine has been continuously investing in industrial fan, human defence pipeline, environmental protection ventilation and other industries, from angle iron punching machine, angle iron flange automatic welding, CNC automatic roll round machine, straight seam welding (vertical/horizontal), automatic flanging machine, shrimp elbow automatic welding, fan impeller automatic welding, automatic welding of the related line, round flange automatic welding, pipe butt automatic welding, CNC spinning machine to the complete set of laser cutting production line, round pipe coiling and welding production line, the company can provide one-stop solutions and global services. The professional R&D team protects the mechanical structure, software control and process route of the products; the competent production management team strictly controls the quality of the equipments; the efficient after-sales team provides customers with attentive service. Positive innovation, keep improving, let welding become more simple.

Direct Manufacturer

Quality Control

Local Support

What They Say

Testimonials

"These precise, reliable HOGI machines have boosted our productivity and output quality. The advanced technology handles complex bends with ease, and the user-friendly interface streamlines our workflow."

Spain customer

"Multifunctional flanging machine, flange flanging, punching, crimping, flare edge, reinforcement, punching optional functions, direct processing and molding! Ventilation fan industry processing the latest machine"

Turkey customer

"Full procurement of HOGI equipment from 4-roll CNC plate rolling machine, elevated straight seam welding machine, shrimp elbow automatic welding machine, robotic air duct laser welding machine! Integrated operation, high efficiency and high precision."

Malaysia customer

"The latest technology of 4-roller rolled plate production line, with fast rolling speed, high efficiency, good precision and simple parameterized setting!!"

USA 2024 Aug