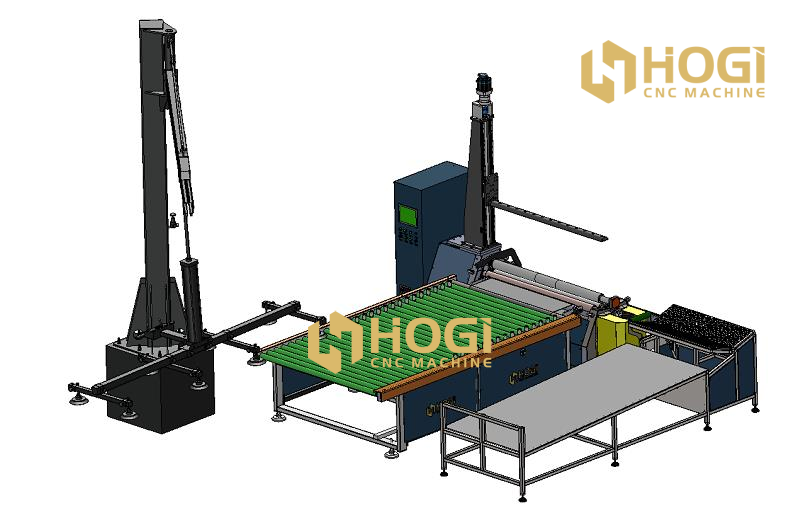

Longitudinal Seam Welding Machine

The Longitudinal Seam Welding Machine is a distinctly green industrial answer designed for particular and continuous welding applications. It performs an important position in industries wherein long, direct welds are required, ensuring consistency, pace, and superior electricity in welded additives. This form of system is broadly used inside the manufacturing of pipes, tanks, cylinders, and diverse sheet metal components that call for accuracy and sturdiness.

Working Principle

The fundamental principle of a Longitudinal Seam Welding Machine in China is based totally totally on turning into a number of quantities of metal along a right away line through managed warmth and strain. The workpiece is placed at the welding bed, and the clamping device ensures it stays in vicinity at some point of the technique. Relying on the requirement, the device can be characterized with distinct welding techniques such as TIG, MIG, plasma, or resistance welding. The mechanism lets in the welding torch or electrode to journey alongside the seam with ordinary pace, which guarantees uniform penetration and best weld best.

Design and Construction

The design of the device is adapted to meet the needs of heavy-duty production. It normally consists of an inflexible frame, a precision clamping mechanism, a movable welding carriage, and a sophisticated manipulator machine. The clamping machine prevents distortion of the cloth in the course of the welding manner, while the carriage guarantees clean and managed movement of the welding head. Modern machines are regularly ready with CNC controls that permit operators to software parameters for exceptional materials, thicknesses, and seam lengths.

Industrial Applications

This gadget unearths software in a huge range of industries. Inside the automobile quarter, it’s far used for manufacturing fuel tanks, exhaust systems, and other cylindrical components. In the aerospace enterprise, it contributes to the production of lightweight yet strong systems. The electricity zone also has advantages from its use in making boilers, strain vessels, and pipelines. Food processing and pharmaceutical system producers rely on it for creating hygienic chrome steel boxes, because the system can produce smooth, clean, and defect-free welds.

Advantages of Seam Welding

One of the foremost blessings of the Longitudinal Seam Welding Machine Manufacturer in China is its ability to provide exceptionally repeatable and uniform welds over prolonged lengths. It reduces the possibility of human blunders, which is commonplace in guide welding. The automation characteristic now not only enhances productiveness but also minimizes fabric wastage. For the reason that method may be tailored to special welding strategies, the device offers flexibility for numerous programs. Some other benefit is its capacity to preserve excessive structural integrity of welded joints, which is important in crucial industries like aerospace and strength.

Modern Innovations

With technological improvements, today’s Longitudinal Seam Welding Machine includes better features together with computerized loading structures, advanced cooling mechanisms, real-time tracking, and progressed person interfaces. Many machines are also incorporated with sensors and comment systems to ensure precision and discover flaws immediately. A few even comprise robot structures for completely automated production traces, lowering reliance on guide intervention.

About Longitudinal Seam Welding Machine

The Longitudinal Seam Welding Machine Supplier in China stands as a cornerstone in cutting-edge production processes, supplying efficiency, reliability, and accuracy. Its capacity to supply continuous, defect-loose welds has made it an crucial tool across a couple of industries. With the ongoing improvement of automation and smart technology, those machines are predicted to turn out to be even extra superior, contributing to higher productivity and improved high-quality standards in commercial fabrication.

Why HOGI CNC

HOGI CNC machine has been continuously investing in industrial fan, human defence pipeline, environmental protection ventilation and other industries, from angle iron punching machine, angle iron flange automatic welding, CNC automatic roll round machine, straight seam welding (vertical/horizontal), automatic flanging machine, shrimp elbow automatic welding, fan impeller automatic welding, automatic welding of the related line, round flange automatic welding, pipe butt automatic welding, CNC spinning machine to the complete set of laser cutting production line, round pipe coiling and welding production line, the company can provide one-stop solutions and global services. The professional R&D team protects the mechanical structure, software control and process route of the products; the competent production management team strictly controls the quality of the equipments; the efficient after-sales team provides customers with attentive service. Positive innovation, keep improving, let welding become more simple.

Direct Manufacturer

Quality Control

Local Support

What They Say

Testimonials

"HOGI hydraulic two-roller rolled production line stainless steel duct chimney processing, efficient and accurate."

Spain Customer

"HOGI customizes all the machines according to the customer's product requirements, meets the customer's product technical solutions, and serves the world.."

New Zealand Designation

"HOGI industrial ventilation fan axial fan centrifugal fan flange automatic flanging punching forming machine."

Canada Designation

"HOGI High precision straight seam welding machine with optional laser, tig, MIG welding machine, high precision configuration, high efficiency. Use long time!"

Israel 2025 MAY