Machine Overview

The machine is fully servo-driven, digitized control, advanced structure of the machine, superior performance, high efficiency, in the international and domestic industry are in the leading level.

Our full servo CNC four-roller plate rolling machine has features:

1. Side roller linear displacement, pre-bending effect is good;

2. The active roller, pressure roller and both side rollers are all controlled by servo motors;

3. Good synchronization, high precision, fast response speed and other advantages.

1-2 The following users are suitable for using the four-roller bending machine

1. First time users, because it is one of the easiest rollers to operate.

2. Inexperienced operators who require high productivity.

3. Require high precision and improved quality

4. Wish to have only one operator to reduce labor cost.

1-3 Features of this machine

1, full servo drive, high efficiency and energy saving (drive power equivalent to 60% of the traditional), rolling work is safer and more reliable than other types of rolling machine.

2,Permanent lubrication technology (no need to refuel the bearings during the life of the bearings, they have been refilled at the factory)

3, adjustable clamping pressure (no slippage, productivity 2-3 times higher than the three-roller plate rolling machine), the clamping force between the upper and lower rolls on the plate can be set through the screen on the servomotor torque force to adjust the different thicknesses and widths of the plate rolled relative to the value of the required pressure.

4, can be rolled on the roll diameter 1.5 times the cylinder, the end of the rolled sheet pre-bending straight edge length is smaller than other types of rolling machine.

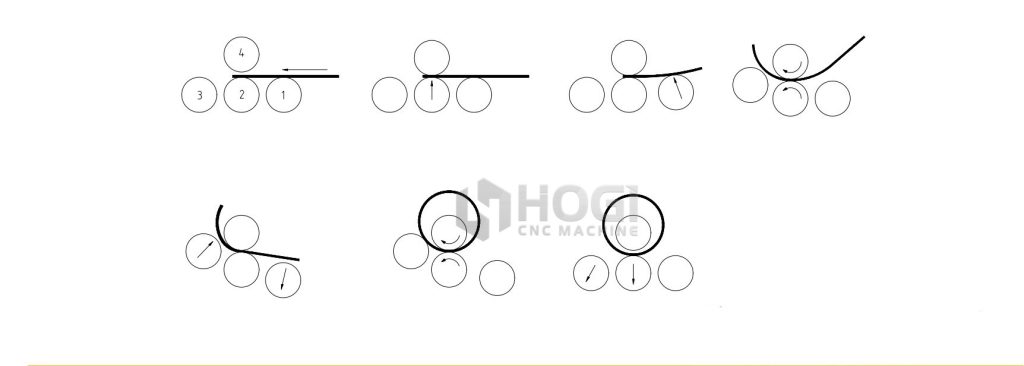

The principle of work (see figure)

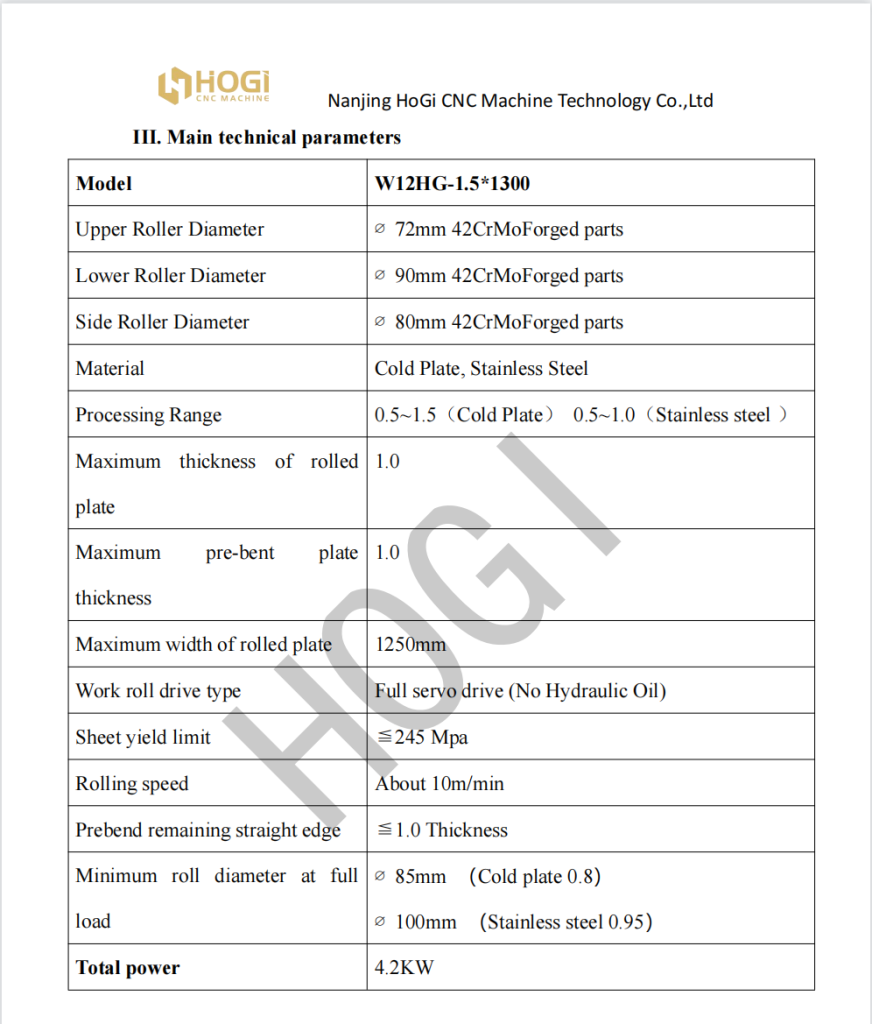

The main technical parameters

Advantageous technology:

IV. Main Structure

4-1, The main structure

The main structure of the equipment is composed of upper roller device, lower roller device, side roller device, main transmission device, tipping device, left and right side frame and chassis.

The upper roller is the active roller, powered by servo motor, the upper roller can be forward and reverse, the lower roller and both side rollers are the driven rollers. Side rollers make linear lifting and lowering movement along the frame rail, and the rotation of side rollers is driven by the friction between the steel plate and each roller. The upward and downward movement of the lower and side rollers is driven by servo motors and implemented by ball screws, and the overturning and resetting of the inverted head is realized by pneumatic cylinders.

The frame is welded steel plate structure, annealed after welding to eliminate stress. The two side roller lifting is located between the left and right side of the frame, the lower roller lifting is located in the middle of the machine, the servo motor through the synchronous belt wheel mechanism and the work roller direct drive. All operations are carried out on the panel of the control desk on the side of the machine.

The upper roll is fixed in position and is held down by a counterbalance device mounted at the rear of the machine, and a pneumatic cylinder performs the tipping and resetting of the inverted head portion of the upper roll.

4-2、Using new type of rolling bearings

The machine work roll journal all with new rolling mill rolling bearing, new rolling bearing for rolling mill adopts international advanced technology, developed by the bearing factory in accordance with the international advanced standards, to fill the gaps in the country, long bearing life, energy saving. The adoption of upper and lower roll drive technology removes the distribution box, improves the main transmission efficiency, reduces the main transmission power, long service life, low friction resistance, non-slip conditions are greatly improved, and thinner steel plates can be rolled.

Both energy saving and can roll thinner steel plate, roll smaller diameter.

4-3、Drivetrain

4-3-1 Main transmission

The upper roller is the active roller, driven by direct coupling of servo and reducer drive, the material of the four rollers is 42CrMo forging, through rough machining and tempering heat treatment (HB280-300), and refined.

4-3-2、Sub-drive

The lower roller lifting is driven by servo motor drive mechanism to make the lower roller rise and fall, with high synchronization precision. Mechanical transmission lower roller lifting, mechanical gap is large, inaccurate positioning, low efficiency, energy consumption, and its compression force is not easy to control and overload. This structure can meet the synchronization, pressure can also be controlled, there will be no overload phenomenon.

V. Electric control system

The process software operates through PLC programmable control system, high degree of automation in the rolling process, high precision of the products, low failure rate of the equipment, and high working efficiency.

High working efficiency. The characteristics of the software: for the rolled cylinder, no need to repeat the test, can be molded once, the data obtained can be scale rolled standard.

With formula storage function

In the process of time production, the need to roll a variety of specifications of the product, in the use of the process we only need to adjust the parameters of the specifications of a saved to the corresponding formula, in the next time the product is rolled again, you only need to call the product to save the formula can be. This saves the time spent on adjusting the position of the work rollers before each roll, thus improving the processing efficiency.