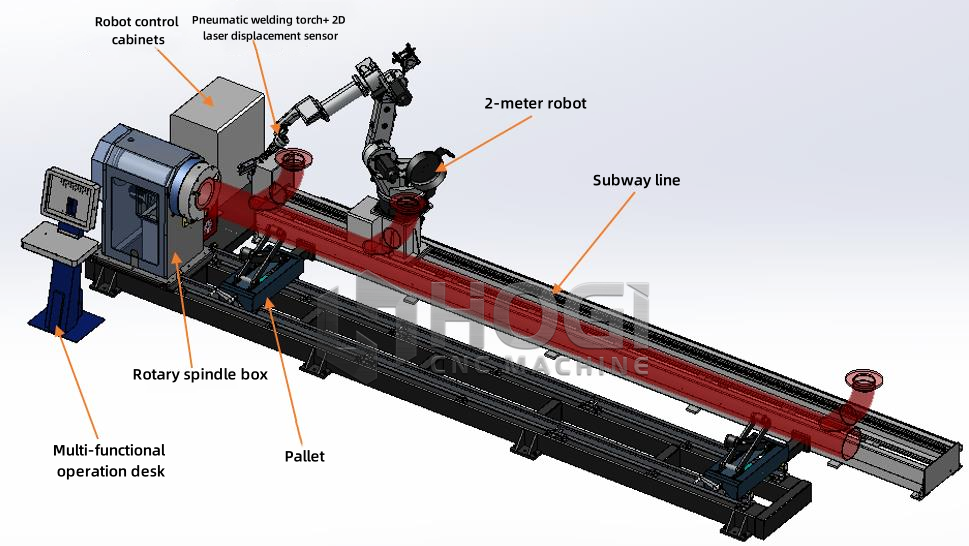

Automatic Welding Robot

Machine Name: Shrimp elbow automatic Welding machine, Fan impeller Robot Automatic welding, intersection line automatic welding robot

Model: Customized

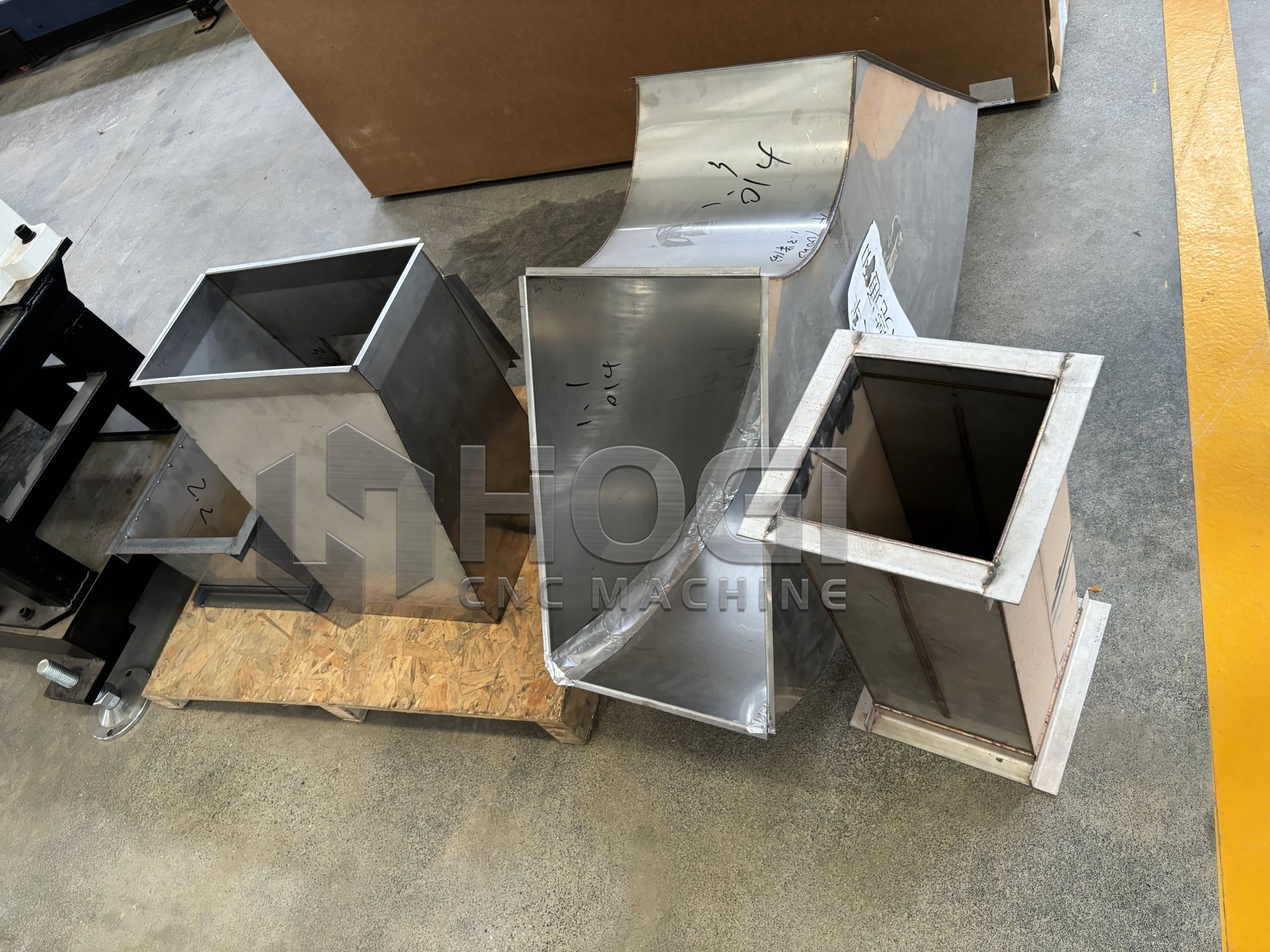

Application Industry:Duct Fan HVAC complete welding equipment Angle steel flange automatic welding,Electromechanical pipeline welding equipment.

Technical Service:Through program parameter input and visual laser positioning, the weld is detected and the welding trajectory is automatically generated. At the same time, analog control is added to the welding process to adjust the current and voltage. It adopts touch screen control and is equipped with an intelligent detection system. It has functions such as power-off protection, welding gun anti-collision, short-circuit memory, and program storage, which can realize welding in all positions.

HOGI Multi-section elbow automatic welding machine, fan impeller robot welding, pipeline intersection line automatic welding robot,:

HOGI company uses Laser vision system in conjunction with a general 6-axis industrial robot to track the weld, measure the weld size data, automatically calculate the weld center position and the required welding parameters, and the robot controls the running trajectory in real time to ensure that the welding gun is always aligned with the weld.

HOGI currently configures an intelligent welding workstation suitable for multi-size workpieces for intelligent production in the wind turbine industry, and has successfully used it in production sites of many factories

· Fully automatic mode, no manual intervention is required during welding;

· The tracking system has a fast response speed and high weld tracking accuracy;

· The weld has a beautiful appearance and good uniformity and consistency;

· Multi-layer and multi-pass weld tracking can be performed;

· Appearance inspection of weld quality (optional);

· Automatic loading and unloading of workpieces (optional).

HOGI fan elbow HVAC complete sets of welding equipment Angle steel flange automatic welding, electromechanical pipeline welding equipment

Industrial fan ducts are widely used in factories, mines, tunnels and other scenes for ventilation, dust removal and cooling; ventilation and air induction of boilers and industrial furnaces; wind tunnel wind source and inflation and propulsion of hovercraft, etc. The quality of the fan casing and impeller, as important components, is related to the efficiency of the fan. Therefore, during the welding process, the welding quality of the fan casing and impeller is also the key to improving the efficiency of the entire fan.

Through program parameter input and visual laser positioning, the weld is detected and the welding trajectory is automatically generated. At the same time, analog control is added to the welding process to adjust the current and voltage. It adopts touch screen control and is equipped with an intelligent detection system. It has functions such as power-off protection, welding gun anti-collision, short-circuit memory, and program storage, which can realize full-position welding.

Functional features

1) Completely non-contact welding, no vibration;

2) Open system, adjustable parameters;

3) Simple workpiece placement, simple and easy operation;

4) General operating failures will automatically alarm and stop, safe and easy to use;

5) Beautiful welds, reliable welding quality, no need for grinding and slag removal

HOGI Laser welding introduction: Laser welding is a new type of laser welding method, mainly for the welding of thin-walled materials and precision parts, and can achieve spot welding, butt welding, lap welding, stack welding, fillet welding, tailoring welding, sealing welding, etc.