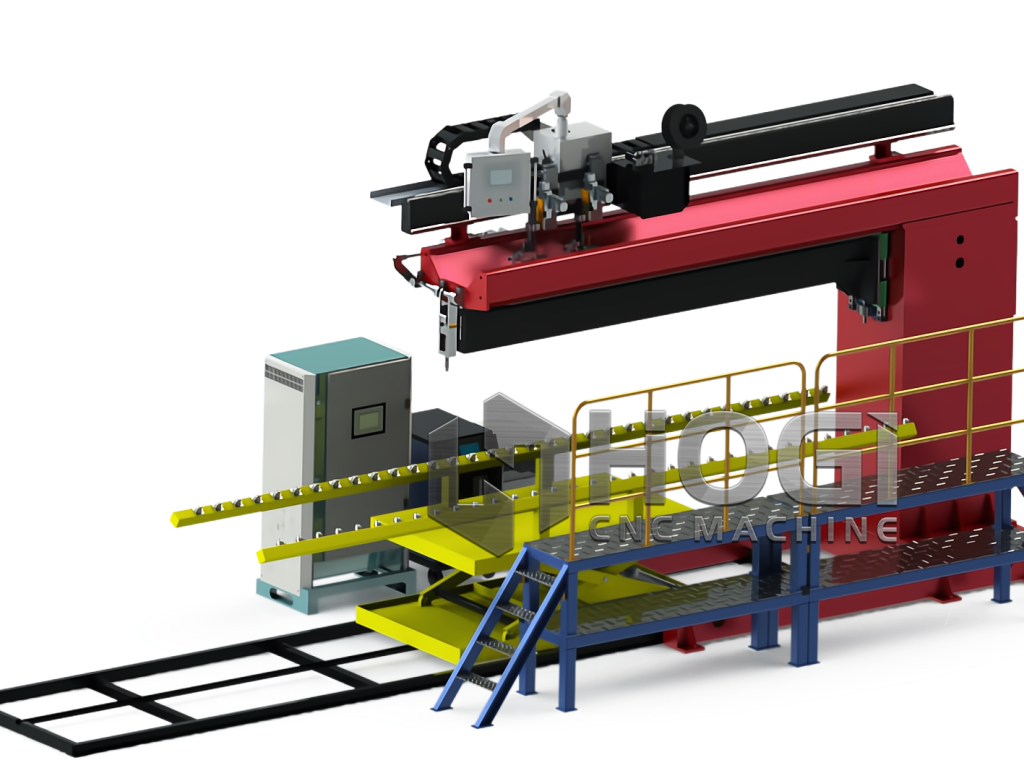

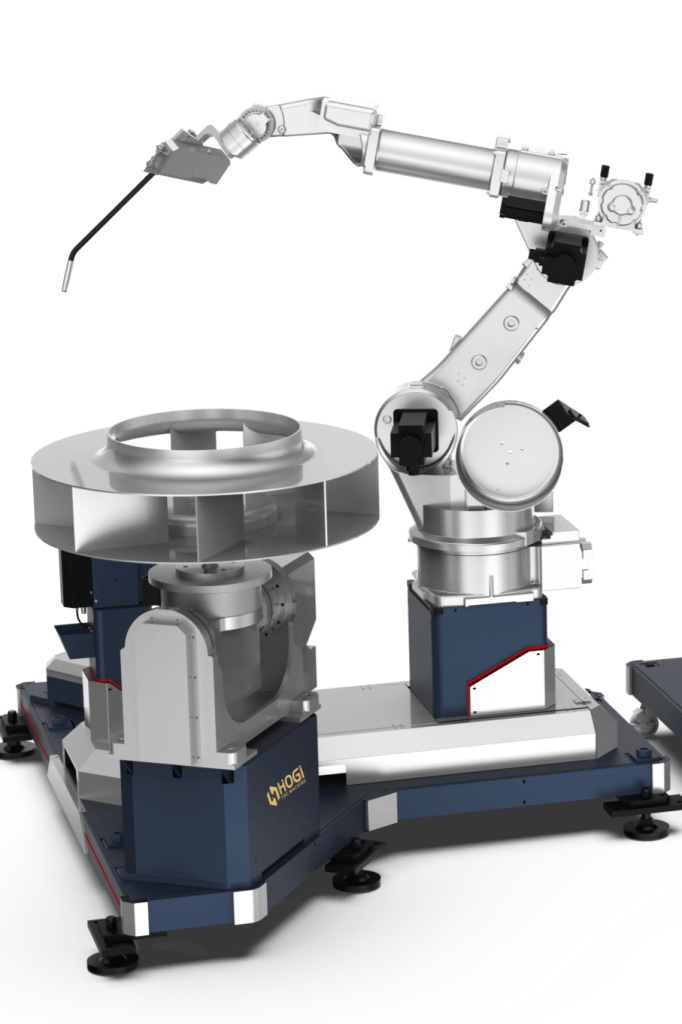

Seam Welding Machine

Seam Welding Machine are superior welding devices designed to sign up for metallic sheets along a continuous seam. Now not like spot welding, which produces isolated weld elements, seam welding creates a continuous weld line, making sure sturdy and leak-evidence joints. These machines are extensively applied in industries in which hermetic or watertight connections are essential, consisting of automobile gasoline tanks, steel bins, kitchen appliances, and piping systems.

How Seam Welding Machines Work

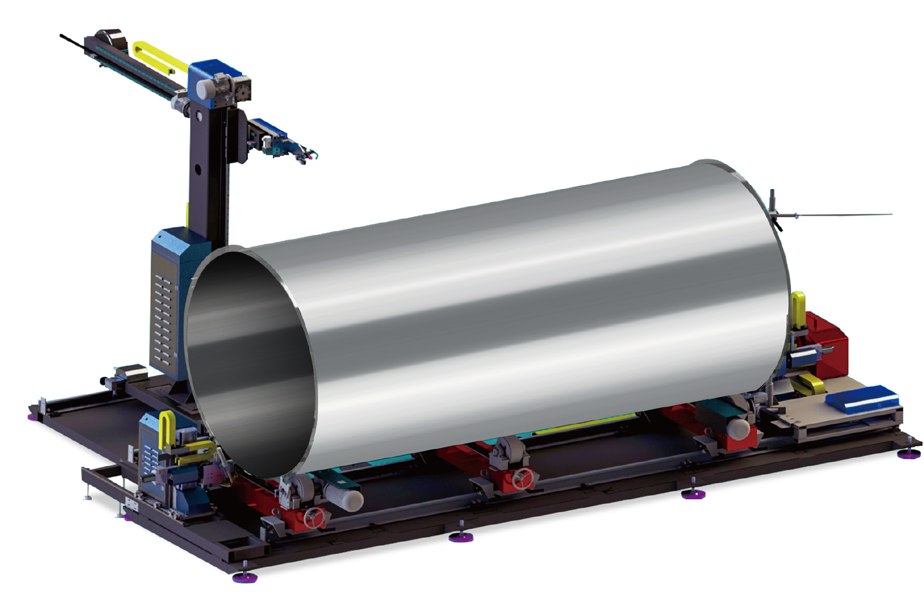

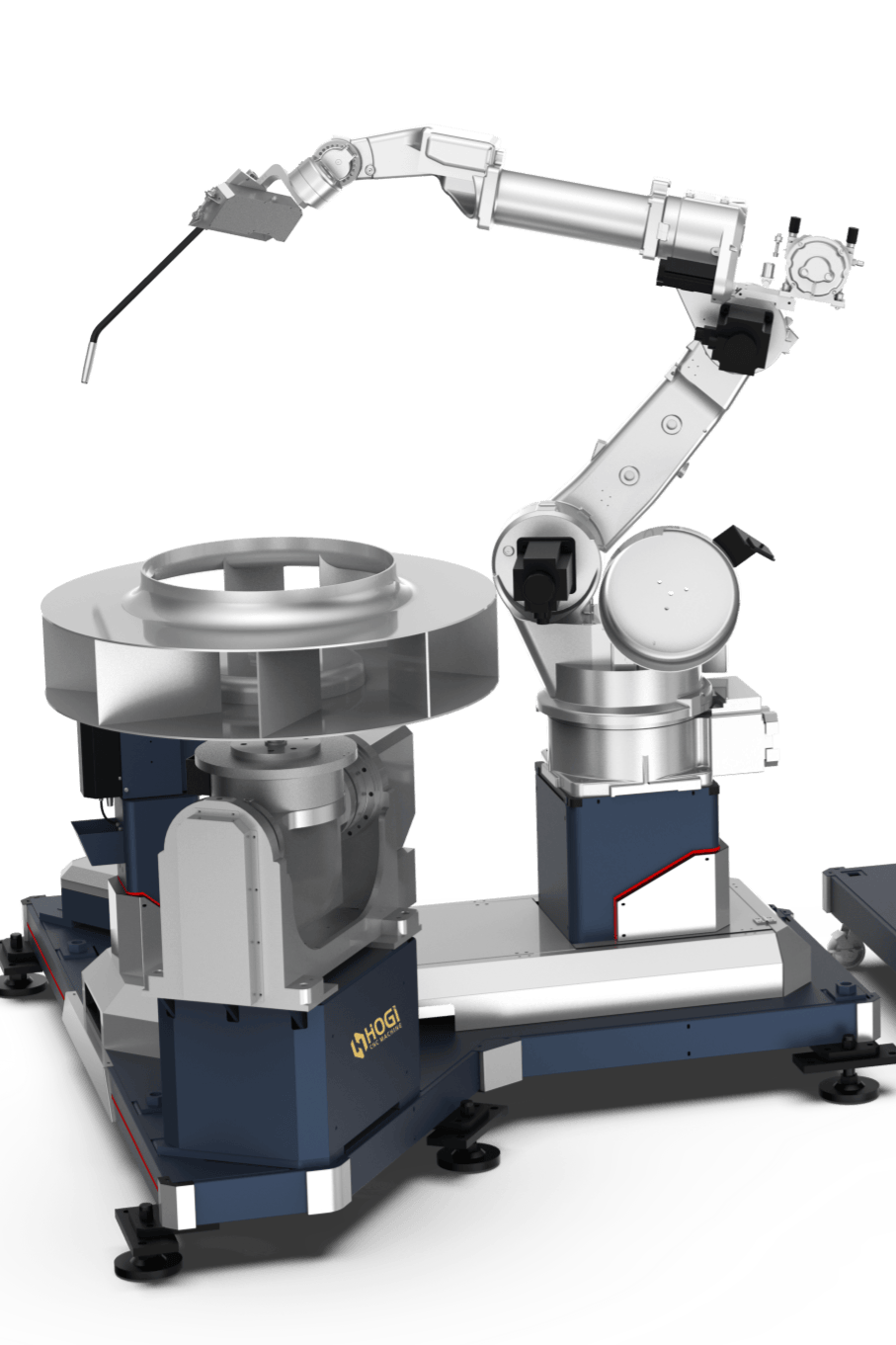

The jogging precept of a Seam Welding Machine in China is based totally on resistance welding. The gadget includes rotating wheel electrodes, which press the metal sheets collectively at the same time as an electric powered contemporary passes through the cloth. The resistance generated on the touch elements produces warmness, causing the metallic to melt and fuse alongside the seam. The wheels rotate continuously, shifting the welded fabric ahead, resulting in a uniform and non-stop weld. This mixture of stress, cutting-edge, and motion guarantees specific welding with minimal cloth distortion.

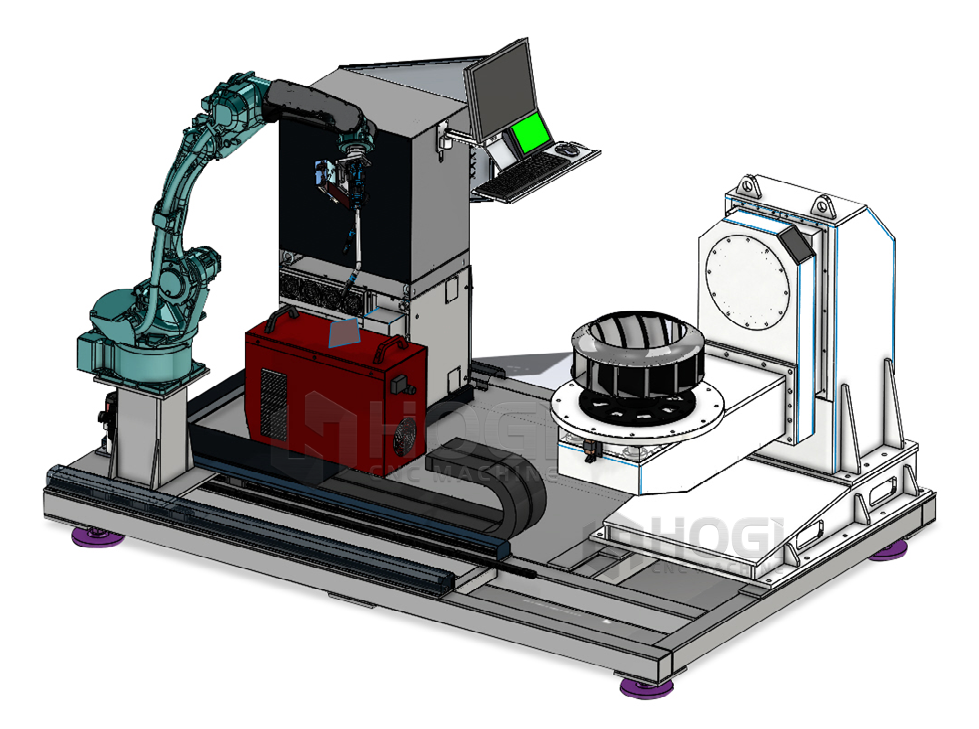

Types of Seam Welding Machines

Seam Welding Machine Supplier in China are to have several kinds to meet specific business desires. The maximum commonplace types are DC seam welding machines and AC seam welding machines. DC seam welders are desired for skinny metal sheets, imparting smoother welds and precise control. AC seam welders are appropriate for thicker materials and high-pace production. Moreover, current machines frequently embody programmable controls and automatic feeding systems, improving productiveness and accuracy.

Applications of Seam Welding Machines

Seam Welding Machine find substantial programs throughout more than one industry. In the car organisation, they’re used for production gasoline tanks, exhaust systems, and body panels, wherein non-prevent, sturdy joints are essential. The packaging company uses seam welding for producing leak-proof metal packing containers and drums. Kitchen appliance producers depend upon those machines to weld gadgets along with chrome steel sinks, washing machines, and cookware. The piping and HVAC organization moreover makes use of seam welding to create durable, high-strain connections in metallic ducts and pipes.

Advantages of Using Seam Welding Machines

One of the number one benefits of seam welding is the introduction of constant and immoderate-electricity welds. The non-prevent weld receives rid of gaps, lowering the chance of leaks and structural weaknesses. Hogicnc additionally increases manufacturing efficiency by the use of automating the welding approach and minimizing the need for manual intervention. These machines produce minimum distortion, making them appropriate for sensitive or skinny metallic sheets. Moreover, the capability to weld extended seams without preventing guarantees smoother finishes and attractive applicable merchandise.

Preservation And Safety Issues

Preserving a Seam Welding Machine is crucial to making sure its lengthy-term average overall performance. Normal inspection of the electrode wheels, cleansing, and calibration are important to prevent defects in welds. Right alignment of the electrodes and adjustment of welding parameters are critical to reap regular consequences. Protection is some different essential issue, as seam welding consists of excessive electric powered currents and warmth. Operators have to observe safety protocols, wear shielding equipment, and ensure proper grounding of the device to prevent injuries.

About Seam Welding Machine

Seam Welding Machine Manufacturer in China are vital tools for industries that require robust, non-stop, and particular welds. Via a way of mixing superior eras with performance, the machines contribute to the manufacturing of super steel merchandise at some point of various sectors. With right protection and operation, Hogicnc can substantially decorate production tactics and product reliability, making them a vital funding for cutting-edge-day commercial enterprise operations.